1. Izinto zokubrasha

(1) I-Titanium kunye ne-alloys yayo esisiseko ayifane iqatywe ngesolder ethambileyo.Iintsimbi zokuzalisa ezisetyenziselwa ukubhobhoza ziquka isiseko sesilivere, isiseko se-aluminium, isiseko se-titanium okanye isiseko se-titanium zirconium.

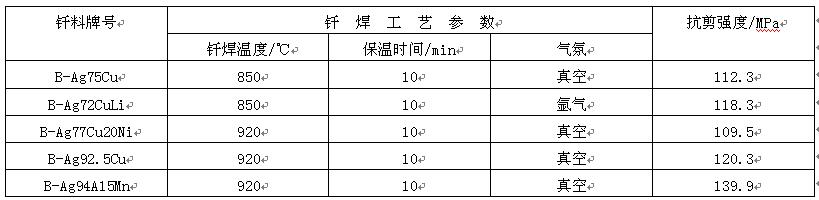

I-solder esekwe kwisilivere isetyenziswa ikakhulu kumacandelo anobushushu obusebenzayo obungaphantsi kwama-540 ℃.Amalungu asebenzisa i-solder yesilivere esulungekileyo anamandla aphantsi, kulula ukuqhekeka, kunye nokumelana ne-corrosion embi kunye nokumelana ne-oxidation.Iqondo lokushisa elivuthayo le-Ag Cu solder lingaphantsi kwesilivere, kodwa ukumanzisa kuncipha ngokunyuka komxholo weCu.I-Ag Cu i-solder equlethe ixabiso elincinci le-Li inokuphucula ukumanzi kunye ne-degree ye-alloying phakathi kwe-solder kunye nesiseko sesinyithi.I-AG Li solder ineempawu zeqondo eliphantsi lokunyibilika kunye nokunciphisa okunamandla.Kufanelekile ukutshisa i-titanium kunye ne-titanium alloys kwindawo yokukhusela.Nangona kunjalo, ivacuum brazing iya kungcolisa iziko ngenxa yokuguquka kweLi.I-Ag-5al- (0.5 ~ 1.0) Intsimbi yesithako se-Mn yeyona ithandwayo yentsimbi yokuzalisa kwiikhomponenti ezinodonga olubhityileyo lwetitanium.Umdibaniso odityanisiweyo une-oxidation elungileyo kunye nokumelana nokubola.Amandla e-shear ye-titanium kunye ne-titanium alloy joints ezidityaniswe ngesinyithi esisisiseko sokuzalisa isilivere kubonisiwe kwiThebhile 12.

Itheyibhile ye-12 iiparamitha zenkqubo yokuqhaqha kunye namandla adibeneyo e-titanium kunye ne-titanium alloys

Iqondo lokushisa lokutshisa i-aluminium esekelwe kwi-solder liphantsi, elingayi kubangela ukuba kwenzeke i-titanium alloy β ukuguqulwa kweSigaba kunciphisa iimfuno zokukhethwa kwezinto zokubethelwa kwe-brazing kunye nezakhiwo.Ukusebenzisana phakathi kwentsimbi yokuzalisa kunye nesiseko sesinyithi siphantsi, kwaye ukuchithwa kunye nokusabalalisa akubonakali, kodwa iplastiki yentsimbi yokuzalisa ilungile, kwaye kulula ukugubungela isinyithi kunye nesiseko sesinyithi kunye, ngoko kunjalo. ifaneleke kakhulu ukubhobhoza i-titanium alloy radiator, isakhiwo se-honeycomb kunye nesakhiwo se-laminate.

I-Titanium esekelwe okanye i-titanium zirconium esekelwe kwi-fluxes ngokubanzi iqulethe i-Cu, i-Ni kunye nezinye izinto, ezinokusasazeka ngokukhawuleza kwi-matrix kwaye ziphendule nge-titanium ngexesha lokugcoba, okubangelwa ukubola kwe-matrix kunye nokwakhiwa kwe-brittle layer.Ngoko ke, ukushisa okutshisayo kunye nexesha lokubamba kufuneka kulawulwe ngokungqongqo ngexesha lokutshiza, kwaye akufanele kusetyenziswe ukubethelwa kwezakhiwo ezinodonga oluncinci kangangoko kunokwenzeka.I-B-ti48zr48be yinto eqhelekileyo ye-Ti Zr solder.Inomanzi afanelekileyo kwi-titanium, kwaye isiseko sesinyithi asinakho ukuthambekela kokukhula okuziinkozo ngexesha lokuqhaqha.

2

(3) I-brazing flux kunye ne-atmosphere ekhuselayo i-titanium, i-zirconium kunye ne-alloys yesiseko inokufumana iziphumo ezanelisayo kwi-vacuum kunye ne-inert atmosphere (i-helium kunye ne-argon).I-argon yococeko oluphezulu luya kusetyenziswa kwi-argon shielded brazing, kwaye indawo yombethe kufuneka ibe -54 ℃ okanye ngaphantsi.I-flux ekhethekileyo equlethe i-fluoride kunye ne-chloride ye-metal Na, K kunye ne-Li kufuneka isetyenziselwe ukuvutha komlilo.

2. Iteknoloji yokubrawuza

Ngaphambi kokutshiza, umphezulu kufuneka ucocwe ngokucokisekileyo, uhlanjululwe kwaye ususwe ifilimu ye-oxide.Ifilimu yeoksidi eshinyeneyo iyakususwa ngendlela yomatshini, indlela yokuqhushumba kwesanti okanye indlela yokuhlamba ityuwa etyhidiweyo.Ifilimu ye-oxide encinci inokupheliswa kwisisombululo esiqulethe i-20% ~ 40% ye-nitric acid kunye ne-2% ye-hydrofluoric acid.

I-Ti, i-Zr kunye nee-alloys zabo azivumelekanga ukuba ziqhagamshelane nomhlaba odibeneyo kunye nomoya ngexesha lokufudumala kwebhobho.I-Brazing inokuqhutyelwa phantsi kokhuseleko lwe-vacuum okanye i-inert gas.Ukufudumeza okuphezulu kwe-induction okanye ukufudumeza ekukhuseleni kungasetyenziswa.Ukufudumeza kwe-induction yeyona ndlela ilungileyo kumacandelo amancinci alinganayo, ngelixa ukutshiza kwisithando somlilo kunenzuzo ngakumbi kumacandelo amakhulu kunye nobunzima.

I-Ni Cr, i-W, i-Mo, i-Ta kunye nezinye izinto ziya kukhethwa njengento yokufudumeza i-Ti, i-Zr kunye ne-alloys yazo.Izixhobo ezinegraphite eveziweyo njengezinto zokufudumeza aziyi kusetyenziselwa ukuphepha ungcoliseko lwekhabhoni.Ukulungiswa kwe-Brazing kuya kwenziwa ngezinto ezinamandla aphezulu obushushu obuphezulu, i-coefficient yokwandisa i-thermal efanayo kwi-Ti okanye i-Zr, kunye ne-reactivity ephantsi ngesiseko sesinyithi.

Ixesha lokuposa: Jun-13-2022