1. Ukuba nesibindi

Ipropathi yokuqhafaza kwe-aluminium kunye ne-aluminium alloys ihlwempuzekile, ngokukodwa kuba ifilimu ye-oxide ebusweni kunzima ukuyisusa.IAluminiyam inobudlelwane obukhulu beoksijini.Kulula ukwenza ifilimu eshinyeneyo, ezinzileyo kunye nephezulu yokunyibilika kwe-oxide ye-Al2O3 kumphezulu.Ngexesha elifanayo, i-aluminium alloys equkethe i-magnesium nayo iya kwenza ifilimu ye-oxide ezinzileyo kakhulu ye-MgO.Baya kuthintela kakhulu ukumanzisa kunye nokusabalalisa i-solder.Kwaye kunzima ukususa.Ngexesha lokugcoba, inkqubo yokuqhafaza inokuthi iqhutywe kuphela nge-flux efanelekileyo.

Okwesibini, ukusebenza kwe-aluminium kunye ne-aluminium alloy brazing kunzima.I-melting point ye-aluminium kunye ne-aluminium alloy ayifani kakhulu naleyo yensimbi yokuqhafaza esetyenzisiweyo.Uluhlu olukhethwayo lobushushu lokubhengeza lumxinwa kakhulu.Ulawulo oluncinci lweqondo lokushisa olungafanelekanga lulula ukubangela ukushisa okanye ukunyibilika kwesiseko sesinyithi, okwenza inkqubo yokuqhayisa inzima.Ezinye ii-alloys ze-aluminiyam eziqiniswe kunyango lobushushu ziya kubangela ukuba izinto ezithambileyo zithobeke ezifana nokuguga okanye ukucima ngenxa yokufudumala kwebrazi, okuya kunciphisa iipropati ze-brazed joints.Ngexesha lokuvutha komlilo, kunzima ukugweba ubushushu kuba umbala we-aluminium alloy awutshintshi ngexesha lokufudumala, okwandisa iimfuno zenqanaba lokusebenza komsebenzisi.

Ngaphezu koko, ukuxhathisa ukubola kwe-aluminiyam kunye ne-aluminium alloy brazed joints ichaphazeleka ngokulula zizinyithi zokuzalisa kunye ne-fluxes.Amandla e-electrode ye-aluminiyam kunye ne-aluminium alloy yahluke kakhulu kwi-solder, enciphisa ukuxhathisa ukubola kwe-joint, ngakumbi kwi-solder ethambileyo edibeneyo.Ukongeza, uninzi lwee-fluxes ezisetyenzisiweyo kwi-brazing ye-aluminiyam kunye ne-alloys ye-aluminium inokonakala okuqinileyo.Nangona zihlanjululwe emva kokuqhaqha, impembelelo ye-fluxes kwi-corrosion resistance of joints ayiyi kupheliswa ngokupheleleyo.

2. Izinto zokutshisa

(1) Ukuxutywa kwe-aluminium kunye ne-aluminium alloys yindlela engavamile ukusetyenziswa, kuba ukubunjwa kunye ne-electrode ye-brazing ye-brazing filler metal kunye nesiseko sesinyithi sihluke kakhulu, okulula ukubangela ukubola kwe-electrochemical of joint.I-solder ethambileyo kakhulu ithatha i-zinc esekwe kwi-solder kunye ne-tin lead solder, enokwahlulwa ibe yi-solder yobushushu obuphantsi (150 ~ 260 ℃), i-solder yobushushu obuphakathi (260 ~ 370 ℃) kunye ne-solder yobushushu obuphezulu (370 ~ 430 ℃) ngokwe uluhlu lobushushu.Xa i-tin lead solder isetyenzisiwe kwaye ubhedu okanye i-nickel ifakwe ngaphambili kwi-aluminium surface ukuze idibanise, i-corrosion kwi-interface edibeneyo inokuthintelwa, ukwenzela ukuba kuphuculwe ukuxhathisa kwe-corrosion ye-joint.

I-Brazing ye-aluminium kunye ne-aluminium alloys isetyenziswa ngokubanzi, njengesikhokelo sokucoca, i-evaporator, i-radiator kunye nezinye izinto.Kuphela ziintsimbi zokuzalisa ezisekwe kwi-aluminiyam ezinokusetyenziselwa ukubrawuza i-aluminiyam kunye ne-alloys ye-aluminium, phakathi kwayo i-aluminium silicon filler metal zezona zisetyenziswa kakhulu.Umda othile wokusetyenziswa kunye namandla okucheba amalunga aqhagamshelweyo aboniswe kwiThebhile 8 kunye netheyibhile 9 ngokulandelelanayo.Nangona kunjalo, indawo yokunyibilika yale solder isondele kwisiseko sesinyithi, ngoko ke ubushushu bokufudumala kufuneka bube ngqongqo kwaye buchaneke ngokuchanekileyo ngexesha lokugcoba ukuphepha ukugqithisa okanye ukunyibilika kwesiseko sesinyithi.

Itheyibhile yesi-8 yokusetyenziswa komda wesinyithi sokuzalisa i-aluminiyam kunye ne-aluminium alloys

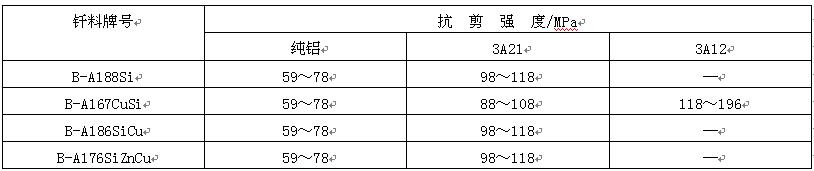

Itheyibhile ye-9 yamandla okucheba ye-aluminiyam kunye ne-aluminium alloy joints ezidityaniswe nge-aluminiyam ye-silicon yokuzalisa isinyithi

I-aluminiyam i-silicon solder idla ngokunikezelwa ngendlela yomgubo, intlama, ucingo okanye iphepha.Kwezinye iimeko, iipleyiti ze-solder ezihlanganisiweyo kunye ne-aluminiyam njengengundoqo kunye ne-aluminium ye-silicon solder njengoko i-cladding isetyenziswa.Olu hlobo lwe-solder composite plate yenziwe ngendlela ye-hydraulic kwaye isoloko isetyenziswa njengenxalenye yamacandelo okubrawuza.Ngexesha lokugcoba, isinyithi sokuzalisa i-brazing kwi-plate edibeneyo iyancibilika kwaye igeleza phantsi kwesenzo se-capillary kunye ne-gravity yokuzalisa i-gap edibeneyo.

(2) I-Flux kunye negesi yokukhusela i-aluminium kunye ne-aluminium alloy brazing, i-flux ekhethekileyo isoloko isetyenziselwa ukususa ifilimu.I-organic flux esekelwe kwi-triethanolamine, efana ne-fs204, isetyenziswa kunye ne-solder ethambileyo yobushushu obuphantsi.Inzuzo yalo mbhobho kukuba inempembelelo encinci ye-corrosion kwisiseko sesinyithi, kodwa iya kuvelisa inani elikhulu legesi, eliya kuchaphazela ukumanzisa kunye ne-caulking ye-solder.I-flux esebenzayo esekelwe kwi-zinc chloride, efana ne-fs203 kunye ne-fs220a, isetyenziselwa ubushushu obuphakathi kunye ne-solder ethambileyo ephezulu.I-flux esebenzayo iyingozi kakhulu, kwaye intsalela yayo kufuneka isuswe emva kokuqhaqha.

Okwangoku, i-brazing ye-aluminium kunye ne-aluminium alloys isalawulwa ngokususwa kwefilimu ye-flux.I-brazing flux esetyenzisiweyo iquka i-chloride esekelwe kwi-flux kunye ne-fluoride based flux.I-Chloride esekelwe kwi-flux inamandla amakhulu okususa ifilimu ye-oxide kunye ne-fluidity efanelekileyo, kodwa inempembelelo enkulu eyingozi kwisiseko sesinyithi.Intsalela yayo kufuneka isuswe ngokupheleleyo emva kokubrawuza.I-fluoride esekelwe kwi-fluoride luhlobo olutsha lwe-flux, enefuthe elihle lokususa ifilimu kwaye akukho mhlwa kwisiseko sesinyithi.Nangona kunjalo, inendawo ephezulu yokunyibilika kunye nokuzinza okuphantsi kwe-thermal, kwaye inokusetyenziswa kuphela nge-aluminium solder ye-silicon.

Xa ukubetha i-aluminium kunye ne-aluminium alloys, i-vacuum, i-neutral okanye i-inert atmosphere isoloko isetyenziswa.Xa kusetyenziswa i-vacuum brazing, idigri yevacuum iya kufikelela ngokubanzi kumyalelo we-10-3pa.Xa i-nitrogen okanye i-argon gas isetyenziselwa ukukhusela, ucoceko kufuneka lube phezulu kakhulu, kwaye indawo yombethe kufuneka ibe ngaphantsi kwe -40 ℃

3. Iteknoloji yokubrawuza

I-Brazing ye-aluminium kunye ne-aluminium alloys ineemfuno eziphezulu zokucocwa kwendawo yokusebenza.Ukuze ufumane umgangatho omhle, i-oyile ye-oyile kunye nefilimu ye-oxide phezu komhlaba kufuneka isuswe ngaphambi kokutshisa.Susa i-oil stain phezu komhlaba kunye nesisombululo se-Na2CO3 samanzi kwiqondo lokushisa lama-60 ~ 70 ℃ nge-5 ~ 10min, uze uhlambulule ngamanzi acocekileyo;Ifilimu ye-oxide ye-surface inokususwa ngokutshiza nge-NaOH isisombululo samanzi kwiqondo lokushisa kwe-20 ~ 40 ℃ ye-2 ~ 4min, kwaye emva koko ihlanjwe ngamanzi ashushu;Emva kokususa i-oil stain kunye nefilimu ye-oxide phezu komhlaba, i-workpiece iya kunyangwa nge-HNO3 isisombululo se-aqueous ye-gloss ye-2 ~ 5min, emva koko ihlambuluke emanzini asebenzayo kwaye ekugqibeleni yomiswe.Isixhobo sokusebenza esinyangwa ngezi ndlela asiyi kuchukunyiswa okanye singcoliswe ngolunye ukungcola, kwaye siya kugqunywa ngaphakathi kwe-6 ~ 8h.Kungcono ukugcoba ngokukhawuleza ukuba kunokwenzeka.

Iindlela zokubethelwa kwe-aluminium kunye ne-aluminium alloys ikakhulu zibandakanya ukuvutha komlilo, i-soldering iron brasing kunye ne-furnace brazing.Ezi ndlela ngokuqhelekileyo zisebenzisa i-flux kwi-brazing, kwaye zineemfuno ezingqongqo kwiqondo lokushisa lokushisa kunye nexesha lokubamba.Ngexesha lokugqabhuka kwedangatye kunye nokutywinwa kwentsimbi, kunqande ukufudumeza umsinga ngokuthe ngqo ngomthombo wobushushu ukunqanda ubushushu bobushushu kunye nokusilela.Ekubeni i-aluminiyam inokunyibilika kwi-solder ethambileyo enomxholo ophezulu we-zinc, ukufudumeza kufuneka kumiswe xa i-joint yenziwe ukuphepha isiseko sentsimbi.Kwezinye iimeko, ukunyanzeliswa kwe-aluminium kunye ne-aluminium alloys ngamanye amaxesha ayisebenzisi i-flux, kodwa isebenzisa iindlela ze-ultrasonic okanye ze-scraping ukususa ifilimu.Xa usebenzisa i-scraping ukususa ifilimu yokugcoba, qale ufudumeze i-workpiece kwiqondo lokushisa lokutshisa, kwaye emva koko ukhuphe inxalenye ye-brazing ye-workpiece kunye nesiphelo sentonga ye-solder (okanye isixhobo sokukrala).Ngelixa uphula ifilimu ye-oxide yomhlaba, isiphelo se-solder siya kunyibilika kwaye simanzise isiseko sesinyithi.

Iindlela zokubrawuza ze-aluminiyam kunye ne-aluminium alloys ikakhulu zibandakanya ukuvutha komlilo, ukuvutha kwesithando somlilo, i-dip brazing, i-vacuum brazing kunye ne-gas shielded brazing.Ukuvutha komlilo kusetyenziswa kakhulu kwizixhobo ezincinci zokusebenza kunye nemveliso yeqhekeza elinye.Ukuze ugweme ukungaphumeleli kwe-flux ngenxa yoqhagamshelwano phakathi kokungcola kwi-acetylene kunye ne-flux xa usebenzisa i-oxyacetylene flame, kuyafaneleka ukusebenzisa i-petroli edibeneyo yomlilo womoya kunye nokunciphisa okuncinci ukukhusela i-oxidation yesiseko sesinyithi.Ngethuba lokutshiza okuthe ngqo, i-brazing flux kunye ne-filler metal ingafakwa kwindawo edibeneyo ngaphambili kwaye ishushu ngexesha elifanayo kunye nomsebenzi;I-workpiece inokufudunyezwa kwiqondo lokushisa lokuqala, kwaye emva koko i-solder editywe nge-flux ingathunyelwa kwindawo yokuqhayisa;Emva kokuba i-flux kunye ne-filler metal iyancibilika, i-flame yokufudumeza iya kususwa ngokukhawuleza emva kokuba isinyithi sokuzalisa sigcwaliswe ngokulinganayo.

Xa i-aluminiyam kunye ne-alloy ye-aluminiyam kwiziko lomoya, isinyithi sokutshisa isinyithi siya kulungiswa kwangaphambili, kwaye i-brazing flux iya kunyibilika emanzini adibeneyo ukuze kulungiswe isisombululo esinzima kunye noxinzelelo lwe-50% ~ 75%, kwaye emva koko igqunywe okanye itshizwe. umphezulu wokugquma.Umlinganiselo ofanelekileyo we-powder brazing flux unokugqunywa kwi-brazing filler metal kunye ne-brazing surface, emva koko i-weldment edibeneyo iya kufakwa kwisithando somlilo sokufudumeza ukutshisa.Ukuze uthintele isiseko sesinyithi ekugqithiseni okanye nokuba sinyibilike, ubushushu bokufudumala kufuneka bulawulwe ngokungqongqo.

I-paste okanye i-foil solder isetyenziswa ngokubanzi ukudipha i-aluminiyam kunye ne-alloys ye-aluminium.Isixhobo sokusebenza esidityanisiweyo siya kufudunyezwa ngaphambi kokuba sitshise ukwenza iqondo lobushushu libe kufutshane neqondo lobushushu, emva koko lintywiliselwe kwi-brazing flux for brazing.Ngethuba lokutshisa, ukushisa kwe-brazing kunye nexesha lokubhobhoza kuya kulawulwa ngokungqongqo.Ukuba iqondo lokushisa liphezulu kakhulu, isiseko sesinyithi silula ukuchithwa kwaye i-solder kulula ukulahleka;Ukuba iqondo lokushisa liphantsi kakhulu, i-solder ayincibiliki ngokwaneleyo, kwaye izinga lokubhobhoza liyancipha.Ukushisa okutshisayo kuya kugqitywa ngokohlobo kunye nobukhulu besiseko sesinyithi, ukubunjwa kunye nenqanaba lokunyibilika kwentsimbi yokuzalisa, kwaye ngokuqhelekileyo phakathi kobushushu be-liquid yentsimbi yokuzalisa kunye nobushushu be-solidus yesiseko sesinyithi.Ixesha lokuntywila le-workpiece kwi-bath flux kufuneka liqinisekise ukuba i-solder inokunyibilika ngokupheleleyo kwaye ihambe, kwaye ixesha elixhasayo akufanele libe lide kakhulu.Ngaphandle koko, i-silicon element kwi-solder inokusasazeka kwisiseko sesinyithi, isenza isiseko sesinyithi kufuphi nomthungo sibe brittle.

Kwi-vacuum brazing ye-aluminium kunye ne-aluminium alloys, ii-activators zetsimbi zihlala zisetyenziselwa ukuguqula ifilimu ye-oxide ye-aluminium kunye nokuqinisekisa ukumanzisa kunye nokusabalalisa i-solder.I-Magnesium inokusetyenziswa ngokuthe ngqo kwi-workpiece ngendlela yeengqungquthela, okanye ifakwe kwindawo yokuqhafaza ngendlela ye-steam, okanye i-magnesium inokongezwa kwi-aluminium solder ye-silicon njenge-alloy element.Kwi-workpiece enesakhiwo esiyinkimbinkimbi, ukwenzela ukuba kuqinisekiswe umphumo opheleleyo womphunga we-magnesium kwisiseko sesinyithi kunye nokuphucula umgangatho wokuqhafaza, amanyathelo okukhusela asekuhlaleni ahlala ethathwa, oko kukuthi, i-workpiece ifakwe kuqala kwibhokisi yensimbi engenasici (ngokuqhelekileyo eyaziwa ngokuba yibhokisi yenkqubo), kwaye emva koko ibekwe kwisithando somlilo sokufudumeza ukunyanyiswa.I-Vacuum Brazed Aluminiyam kunye ne-aluminium alloy joints inomphezulu ogudileyo kunye neendawo ezixineneyo zebrazed, kwaye akukho mfuneko yokuba zicocwe emva kokugqatswa;Nangona kunjalo, izixhobo ze-vacuum brazing zibiza kakhulu, kwaye umphunga we-magnesium ungcolisa isithando somlilo ngokunzulu, ngoko kufuneka sicocwe kwaye sigcinwe rhoqo.

Xa i-aluminium ye-brazing kunye ne-aluminium alloys kwi-neutral okanye i-inert atmosphere, i-activator ye-magnesium okanye i-flux ingasetyenziselwa ukususa ifilimu.Xa i-activator ye-magnesium isetyenziselwa ukususa ifilimu, inani le-magnesium efunekayo liphantsi kakhulu kunelo lokutshiza kwe-vacuum.Ngokubanzi, i-w (mg) imalunga ne-0.2% ~ 0.5%.Xa umxholo we-magnesium uphezulu, umgangatho wokudibanisa uya kuncitshiswa.Indlela ye-NOCOLOK yokubhuqa usebenzisa ifluoride flux kunye nokhuseleko lwenitrogen yindlela entsha ephuhliswe ngokukhawuleza kwiminyaka yakutshanje.Ekubeni intsalela ye-fluoride flux ayifuni ukufuma kwaye ayinayo i-aluminium, inkqubo yokususa i-flux i-residue emva kokuqhawula i-brazing ingashiywa.Ngaphantsi kokukhuselwa kwe-nitrogen, kuphela umlinganiselo omncinci we-fluoride flux kufuneka ugqunywe, isinyithi sokuzalisa sinokumanzisa kakuhle isiseko sesinyithi, kwaye kulula ukufumana amalunga adityanisiweyo aphezulu.Okwangoku, le ndlela yokugaya i-NOCOLOK isetyenziswe kwimveliso yobuninzi be-radiator ye-aluminium kunye nezinye izinto.

Kwi-aluminiyam kunye ne-alloy ye-aluminiyam ebrazed kunye ne-fluoride flux, intsalela ye-flux kufuneka isuswe ngokupheleleyo emva kokubrawuza.Intsalela ye-organic brazing flux ye-aluminium inokuhlanjwa kunye nezisombululo eziphilayo ezifana ne-methanol kunye ne-trichlorethylene, ingathathi hlangothi ngesisombululo se-sodium hydroxide yamanzi, kwaye ekugqibeleni ihlanjululwe ngamanzi ashushu nabandayo.I-chloride yintsalela ye-brazing flux ye-aluminium, enokususwa ngokweendlela ezilandelayo;Okokuqala, cwilisa emanzini atshisayo kwi-60 ~ 80 ℃ ye-10min, ucoce ngokucophelela i-residu kwi-brazed joint kunye ne-brush, kwaye uyihlambulule ngamanzi abandayo;Emva koko yicwilise kwi-15% ye-nitric acid yesisombululo se-aqueous ye-30min, kwaye ekugqibeleni uyihlambulule ngamanzi abandayo.

Ixesha lokuposa: Jun-13-2022