1. Izinto zokubrasha

(1)I-Brazing yensimbi ye-carbon kunye ne-alloy ephantsi yensimbi iquka ukubethelwa okuthambileyo kunye nokuqina okunzima.I-solder esetyenziswa ngokubanzi kwi-solder ethambileyo yi-tin lead solder.Ukumanzisa kwe-solder kwintsimbi kwandisa ngokunyuka komxholo we-tin, ngoko i-solder enomxholo ophezulu we-tin kufuneka isetyenziswe ukutywinwa kwamalungu.I-Fesn2 intermetallic compound layer isenokwenziwa kujongano phakathi kwetoti kunye nentsimbi kwisoda yelothe yenkcenkce.Ukuze ugweme ukubunjwa kwe-compound kule layer, ukushisa okutshisayo kunye nexesha lokubamba kufuneka kulawulwe ngokufanelekileyo.Amandla okucheba amakhonkco entsimbi yekhabhoni adityaniswe ngeentsimbi ezininzi zentsimbi eqhelekileyo abonisiwe kwiThebhile 1. Phakathi kwazo, amandla adibeneyo adityaniswe nge-50% w (SN) ngawona aphakamileyo, kwaye amandla adibeneyo adityaniswe nge-antimony free solder aphezulu kunoko. ukuba kunye ne-antimony.

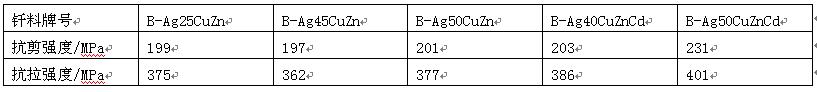

Itheyibhile yoku-1 yamandla okucheba yentsimbi yekhabhoni edityaniswe ngesolder yenkcenkce

Xa ubhobhoza intsimbi yekhabhoni kunye nentsimbi ephantsi, ubhedu olusulungekileyo, i-zinc yobhedu kunye nesilivere yethusi ye-zinc brazing filler metal zisetyenziswa ikakhulu.Ubhedu olucocekileyo lunomgangatho ophezulu wokunyibilika kwaye kulula ukukhupha i-oxidize isiseko sesinyithi ngexesha lokuqhayisa.Isetyenziselwa ikakhulu ukunyanyiswa kwegesi ekhuselekileyo kunye ne-vacuum brazing.Nangona kunjalo, kufuneka kuqatshelwe ukuba i-gap phakathi kwe-brazed joints kufuneka ibe ngaphantsi kwe-0.05mm ukuphepha ingxaki yokuba i-gap edibeneyo ayinakuzaliswa ngenxa ye-fluidity enhle yobhedu.I-carbon steel kunye ne-low alloy iron joints brazed nge-copper ecocekileyo inamandla amakhulu.Ngokubanzi, amandla okucheba yi-150 ~ 215mpa, ngelixa amandla okuqina asasazwa phakathi kwe-170 ~ 340mpa.

Xa kuthelekiswa nobhedu olucocekileyo, indawo yokuncibilika kwe-zinc solder yethusi iyancipha ngenxa yokongezwa kwe-Zn.Ukuze kuthintelwe ukuphuphuma kwe-Zn ngexesha lokugcoba, kwelinye icala, inani elincinci le-Si lingafakwa kwi-solder ye-zinc yobhedu;Ngakolunye uhlangothi, iindlela zokufudumeza ngokukhawuleza kufuneka zisetyenziswe, ezifana ne-flame brazing, i-induction brazing kunye ne-dip brazing.Amalungu entsimbi yekhabhoni kunye nentsimbi ephantsi ye-alloy eboshwe ngentsimbi yobhedu yokuzalisa i-zinc inamandla amahle kunye neplastiki.Umzekelo, amandla okuqina kunye namandla okucheba amajoyinti esinyithi ekhabhoni adityaniswe nge-b-cu62zn solder afikelela kwi-420MPa kunye ne-290mpa.Indawo yokunyibilika ye-solder yesitishi sobhedu sesilivere iphantsi kune-solder ye-zinc yobhedu, ekulungele ukuthungwa kweenaliti.Esi sinyithi sokuzalisa sifanelekile ukutshisa i-flame, i-induction brazing kunye ne-furnace brazing ye-carbon steel kunye ne-alloy iron ephantsi, kodwa umxholo we-Zn kufuneka uncitshiswe kangangoko kunokwenzeka ngexesha lokutshisa isithando somlilo, kwaye izinga lokushisa kufuneka linyuswe.I-Brazing carbon steel kunye nentsimbi ephantsi ye-alloy kunye nesilivere yethusi ye-zinc filler metal inokufumana amajoyina anamandla kunye neplastiki.Idatha ethile idweliswe kwiThebhile 2.

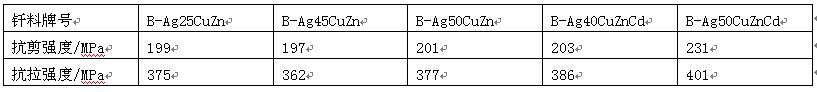

Itheyibhile ye-2 yamandla eentsimbi eziphantsi zekhabhoni ezidityanisiweyo kunye nesiliva yobhedu ye-zinc solder

(2) I-Flux: i-flux okanye igesi yokukhusela iya kusetyenziselwa ukubethelwa kwentsimbi ye-carbon kunye nentsimbi ephantsi.I-flux idla ngokugqitywa yintsimbi ekhethiweyo yokuzalisa kunye ne-brazing method.Xa kusetyenziswa i-tin lead solder, ulwelo oluxutyiweyo lwe-zinc chloride kunye ne-ammonium chloride lunokusetyenziswa njenge-flux okanye enye i-flux ekhethekileyo.Intsalela yale flux idla ngokugqwesa kakhulu, kwaye umdibaniso kufuneka ucocwe ngokungqongqo emva kokubrawuza.

Xa ubhobhoza ngesinyithi se-zinc filler, i-fb301 okanye i-fb302 i-flux iya kunyulwa, oko kukuthi, i-borax okanye umxube we-borax kunye ne-boric acid;Kwi-flame brazing, umxube we-methyl borate kunye ne-asidi ye-formic ingasetyenziselwa njenge-brazing flux, apho umphunga we-B2O3 udlala indima yokususwa kwefilimu.

Xa isilivere yobhedu i-zinc brazing filler metal isetyenziswa, i-fb102, fb103 kunye ne-fb104 i-brazing fluxes ingakhethwa, oko kukuthi, umxube we-borax, i-boric acid kunye nezinye i-fluorides.Intsalela yale flux idleka ukuya kumlinganiselo othile kwaye kufuneka isuswe emva kokugqabhuka.

2. Iteknoloji yokubrawuza

Umphezulu oza kuxutyushwa uya kucocwa ngeendlela zomatshini okanye iikhemikhali zokuqinisekisa ukuba ifilimu ye-oxide kunye ne-organic matter isuswe ngokupheleleyo.Umphezulu ocociweyo awuyi kuba rhabaxa kakhulu kwaye awuyi kubambelela kwiitshiphu zetsimbi okanye ezinye izinto ezimdaka.

Intsimbi yeCarbon kunye nentsimbi ephantsi ye-alloy inokubhobhozwa ngeendlela ezahlukeneyo zokubrawuza eziqhelekileyo.Ngexesha lokutshisa amadangatye, idangatye elingathathi hlangothi okanye elinciphisa kancinci kufuneka lisetyenziswe.Ngexesha lokusebenza, ukufudumeza ngokuthe ngqo kwentsimbi yokuzalisa kunye ne-flux ngumlilo kufuneka kugwenywe kangangoko kunokwenzeka.Iindlela zokufudumeza ngokukhawuleza ezifana ne-induction brazing kunye ne-dip brazing zifaneleke kakhulu ukubethelwa kwentsimbi ecinyiweyo kunye neyomsindo.Ngexesha elifanayo, ukucima okanye ukucima kwiqondo lokushisa eliphantsi kunokushisa kufuneka kukhethwe ukukhusela ukuthotywa kwesiseko sesinyithi.Xa ubhobhoza i-alloy ephantsi yamandla aphezulu ensimbi kwi-atmosphere yokukhusela, kungekhona kuphela ukucoceka okuphezulu kwegesi efunekayo, kodwa kunye ne-gas flux kufuneka isetyenziswe ukuqinisekisa ukumanzisa kunye nokusabalalisa isinyithi sokuzalisa phezu kwesiseko sesinyithi.

I-flux eseleyo inokususwa ngeendlela zeekhemikhali okanye zoomatshini.Intsalela ye-organic brazing flux inokusulwa okanye icocwe ngepetroli, utywala, i-acetone kunye nezinye i-solvents eziphilayo;Iintsalela ze-corrosive flux ezomeleleyo ezifana ne-zinc chloride kunye ne-ammonium chloride aziyi kungathathi hlangothi kwisisombululo se-NaOH samanzi kuqala, kwaye emva koko sicocwe ngamanzi ashushu nabandayo;I-asidi ye-boric kunye ne-boric acid flux residues kunzima ukuyisusa, kwaye ingasombululwa kuphela ngeendlela zoomatshini okanye ukucwiliswa kwexesha elide emanzini akhulayo.

Ixesha lokuposa: Jun-13-2022