Inkcazo kunye nenjongo yokucima

Intsimbi ifudunyezwa kwiqondo lokushisa ngaphezu kwendawo ebalulekileyo ye-Ac3 (insimbi ye-hypoeutectoid) okanye i-Ac1 (intsimbi ye-hypereutectoid), igcinwe ixesha elithile ukuze iyenze i-austenitized ngokupheleleyo okanye iyingxenye, kwaye ipholile ngesantya esikhulu kunesantya esibalulekileyo sokucima. Inkqubo yonyango lobushushu eguqula i-austenite ye-supercooled ibe yi-martensite okanye i-bainite ephantsi ibizwa ngokuba yi-quenching.

Injongo yokucima kukuguqula i-austenite ene-supercooled ibe yi-martensite okanye i-bainite yokufumana i-martensite okanye isakhiwo esisezantsi se-bainite, edityaniswa nokufudumala kumaqondo okushisa ahlukeneyo ukuphucula kakhulu amandla, ukuqina, kunye nokuchasana kwentsimbi. Ukuthwala, amandla okudinwa kunye nokuqina, njl., ukuhlangabezana neemfuno ezahlukeneyo zokusetyenziswa kwamalungu omatshini kunye nezixhobo ezahlukeneyo. Ukucima kungasetyenziselwa ukuhlangabezana neempawu ezikhethekileyo zomzimba kunye neekhemikhali zeentsimbi ezikhethekileyo ezifana ne-ferromagnetism kunye nokumelana nokukhula.

Xa iinxalenye zentsimbi zipholiswa kwindawo yokucima kunye notshintsho kwimo yomzimba, inkqubo yokupholisa ngokubanzi yahlulahlulwe ngokwala manqanaba mathathu alandelayo: inqanaba lefilimu yomphunga, inqanaba lokubilisa, kunye nenqanaba lokuhambisa.

Ukuqina kwentsimbi

Ubunzima kunye nokuqina zizibonakaliso ezimbini zokusebenza ezibonisa ukukwazi kwentsimbi ukucima. Zikwasisiseko esibalulekileyo sokukhetha kunye nokusetyenziswa kwezinto eziphathekayo.

1. Iingcamango zokuqina kunye nokuqina

Ubunzima bubuchule bentsimbi ukufezekisa ubunzima obuphezulu obunokuthi bufikelele xa ucinywa kwaye uqiniswe phantsi kweemeko ezifanelekileyo. Into ephambili emisela ukuqina kwentsimbi ngumxholo wekhabhoni wentsimbi. Ukuchaneka ngakumbi, ngumxholo wekhabhoni ochithwe kwi-austenite ngexesha lokucima kunye nokufudumala. Ukuphakama komxholo wekhabhoni, ukuphakama kokuqina kwentsimbi. . Izinto ezixutywayo kwintsimbi zinempembelelo encinci kwi-hardness, kodwa zinempembelelo enkulu ekuqineni kwentsimbi.

Ubunzima bubhekisela kwiimpawu ezimisela ubunzulu obulukhuni kunye nokusabalalisa ubunzima bentsimbi phantsi kweemeko ezichaziweyo. Oko kukuthi, ukukwazi ukufumana ubunzulu boluhlu oluqinileyo xa isinyithi sicinywa. Yipropati yendalo yentsimbi. Ukuqina okwenene kubonisa ukukhululeka apho i-austenite iguqulela kwi-martensite xa intsimbi icinyiwe. Ikakhulu inxulumene nokuzinza kwe-austenite ye-supercooled yensimbi, okanye kwinqanaba elibalulekileyo lokupholisa intsimbi.

Kufuneka kwakhona kucaciswe ukuba ukuqina kwentsimbi kufuneka kuhluke kubunzulu obusebenzayo beengxenye zetsimbi phantsi kweemeko ezithile zokucima. Ukuqina kwentsimbi yipropati yendalo yentsimbi ngokwayo. Ixhomekeke kuphela kwizinto zayo zangaphakathi kwaye ayinanto yakwenza nezinto zangaphandle. Ubunzulu obusebenzayo bentsimbi yentsimbi ayixhomekeke kuphela kubunzima bentsimbi, kodwa kuxhomekeke kwizinto ezisetyenzisiweyo. Inxulumene nezinto zangaphandle ezifana nendawo yokupholisa kunye nobukhulu bomsebenzi. Ngokomzekelo, phantsi kweemeko ezifanayo ze-austenitizing, ukuqina kwentsimbi efanayo kuyafana, kodwa ubunzulu obusebenzayo bokucima kwamanzi bukhulu kunokucima ioli, kwaye iinxalenye ezincinci zincinci kunokucima ioli. Ubunzulu obusebenzayo bokuqina kwamalungu amakhulu bukhulu. Oku akunakutshiwo ukuba ukucinywa kwamanzi kunobunzima obuphezulu kunokucima ioli. Akunakuthiwa ukuba iindawo ezincinci zinobunzima obuphezulu kunamalungu amakhulu. Kungabonwa ukuba ukuvavanya ukuqina kwentsimbi, impembelelo yezinto zangaphandle ezifana nokubunjwa komsebenzi, ubukhulu, ukupholisa okuphakathi, njl njl. Kufuneka kupheliswe.

Ukongeza, ekubeni ukuqina kunye nokuqina zizinto ezimbini ezahlukeneyo, intsimbi enobunzima obuphezulu emva kokucima ayifuni ukuba nokuqina okuphezulu; kunye nentsimbi enobulukhuni obuphantsi nayo inokuba nokuqina okuphezulu.

2. Izinto ezichaphazela ukuqina

Ukuqina kwentsimbi kuxhomekeke ekuzinzeni kwe-austenite. Nayiphi na into enokuphucula ukuzinza kwe-supercooled austenite, ukuguqula i-C curve ukuya ngasekunene, kwaye ngaloo ndlela ukunciphisa izinga lokupholisa elibalulekileyo kunokuphucula ukuqina kwentsimbi ephezulu. Ukuzinza kwe-austenite ikakhulu kuxhomekeke ekubunjweni kweekhemikhali, ubungakanani beenkozo kunye nokwakheka okufanayo, okuhambelana nokubunjwa kweekhemikhali zentsimbi kunye neemeko zokufudumeza.

3.Indlela yokulinganisa yokuqina

Zininzi iindlela zokulinganisa ukuqina kwentsimbi, ezona zisetyenziswa ngokuqhelekileyo yindlela yokulinganisa i-diameter ebalulekileyo kunye nendlela yokuvavanya ukuqina kokuphela.

(1)Indlela yokulinganisa idiameter ebalulekileyo

Emva kokuba intsimbi icinywe kwindawo ethile, ubukhulu becala xa i-core ifumana yonke i-martensite okanye i-50% yesakhiwo se-martensite ibizwa ngokuba yi-diameter ebalulekileyo, emelwe nguDc. Indlela yokulinganisa i-diameter ebalulekileyo kukwenza uluhlu lweentonga ezingqukuva ezinobubanzi obuhlukeneyo, kwaye emva kokucima, ukulinganisa ubulukhuni be-U igophe elisasazwa kunye nobubanzi kwicandelo ngalinye lesampuli, kwaye ufumane intonga enesakhiwo se-semi-martensite embindini. Ububanzi bentonga ejikelezayo Leyo yi-diameter ebalulekileyo. Ubukhulu be-diameter ebalulekileyo, ukuphakama kokuqina kwentsimbi.

(2) Ukuphelisa indlela yokuvavanya ukucima

Indlela yokuvavanya isiphelo sokucima isebenzisa ubungakanani obuqhelekileyo bokugqibela obucinyiweyo (Ф25mm×100mm). Emva kwe-austenitization, amanzi atshizwa kwelinye icala lomfanekiso kwisixhobo esikhethekileyo ukuze apholise. Emva kokupholisa, ubunzima bulinganiswa kunye nolwalathiso lwe-axis - ukusuka ekupheleni kwamanzi opholileyo. Indlela yokuvavanya umgama wegophe lobudlelwane. Indlela yokuvavanya ukuphela kokuqina yenye yeendlela zokumisela ukuqina kwentsimbi. Iinzuzo zayo kukusebenza okulula kunye noluhlu olubanzi lwesicelo.

4.Ukucima uxinzelelo, ukuguqulwa kunye nokuqhekeka

(1) Uxinzelelo lwangaphakathi lomsebenzi ngexesha lokucima

Xa i-workpiece ipholile ngokukhawuleza kwindawo yokucima, ekubeni i-workpiece inobungakanani obuthile kunye ne-coefficient conductivity ye-thermal nayo ixabiso elithile, i-gradient ethile yokushisa iya kwenzeka kunye necandelo langaphakathi lomsebenzi ngexesha lokupholisa. Ubushushu bomphezulu buphantsi, ubushushu obuphambili buphezulu, kwaye umphezulu kunye namaqondo obushushu aphezulu. Kukho umahluko wobushushu. Ngethuba lenkqubo yokupholisa i-workpiece, kukho izinto ezimbini ezibonakalayo ezibonakalayo: enye kukwandiswa kwe-thermal, njengoko iqondo lokushisa lihla, ubude bomgca we-workpiece buya kuncipha; enye inguqu ye-austenite kwi-martensite xa ubushushu buhla ukuya kwindawo yokuguqulwa kwe-martensite. , eya kwandisa umthamo othile. Ngenxa yokuhluka kweqondo lokushisa ngexesha lokupholisa, inani lokwandiswa kwe-thermal liya kuba lihluke kwiindawo ezahlukeneyo kunye necandelo lomnqamlezo we-workpiece, kwaye uxinzelelo lwangaphakathi luya kuveliswa kwiindawo ezahlukeneyo zomsebenzi. Ngenxa yobukho bokuhluka kobushushu ngaphakathi kwendawo yokusebenza, kusenokubakho iindawo apho iqondo lobushushu lehla ngokukhawuleza kunendawo apho kwenzeka khona i-martensite. Ukuguqulwa, umthamo uyanda, kwaye iinxalenye ezinobushushu obuphezulu zisephezulu kunenqaku kwaye zisekwimeko ye-austenite. Ezi nxalenye zahlukeneyo ziya kuvelisa kwakhona uxinzelelo lwangaphakathi ngenxa yokungafani kweenguqu ezithile zevolumu. Ngoko ke, iintlobo ezimbini zoxinzelelo lwangaphakathi zinokuveliswa ngexesha lokucima kunye nenkqubo yokupholisa: enye ixinzelelo lwe-thermal; enye luxinzelelo lwethishu.

Ngokweempawu zexesha lobukho boxinzelelo lwangaphakathi, lunokwahlulwa lube luxinzelelo olukhawulezileyo kunye noxinzelelo olushiyekileyo. Uxinzelelo lwangaphakathi oluveliswa yi-workpiece ngexesha elithile ngexesha lokupholisa libizwa ngokuba nguxinzelelo olukhawulezayo; emva kokuba i-workpiece ipholile, uxinzelelo olushiyekileyo ngaphakathi kwendawo yokusebenza lubizwa ngokuba luxinzelelo olushiyekileyo.

Uxinzelelo lwe-thermal lubhekiselele kuxinzelelo olubangelwa ukunyuka kwe-thermal okungahambelaniyo (okanye ukucutha okubandayo) ngenxa yokwahlukana kwamaqondo obushushu kwiindawo ezahlukeneyo zomsebenzi xa ishushu (okanye ipholile).

Ngoku thatha i-cylinder eqinile njengomzekelo wokubonisa ukubunjwa kunye nokutshintsha imithetho yoxinzelelo lwangaphakathi ngexesha lokupholisa kwayo. Uxinzelelo lwe-axial kuphela luxoxwa apha. Ekuqaleni kokupholisa, kuba umphezulu upholisa ngokukhawuleza, ukushisa kuphantsi, kwaye kuyancipha kakhulu, ngelixa i-core ipholile, iqondo lokushisa liphezulu, kwaye i-shrinkage incinci. Ngenxa yoko, umphezulu kunye nangaphakathi zithintelwe ngokufanayo, okubangela uxinzelelo oluphezulu phezu komhlaba, ngelixa i-core iphantsi koxinzelelo. uxinzelelo. Njengoko ukupholisa kuqhubeka, ukuhluka kweqondo lokushisa phakathi kwangaphakathi nangaphandle kuyanda, kwaye uxinzelelo lwangaphakathi luyanda ngokufanelekileyo. Xa uxinzelelo lwanda ukugqithisa amandla esivuno kule bushushu, ukuguqulwa kweplastiki kwenzeka. Ekubeni ubukhulu bentliziyo buphezulu kunobo bomphezulu, intliziyo ihlala i-contract axially kuqala. Ngenxa yokuguqulwa kweplastiki, uxinzelelo lwangaphakathi alusayi kunyuka. Emva kokupholisa ixesha elithile, ukuhla kobushushu bomhlaba kuya kuncipha ngokuthe ngcembe, kwaye ukucutheka kwayo kuya kuncipha ngokuthe ngcembe. Ngeli xesha, undoqo usacutheka, ngoko ke uxinzelelo oluphezulu kumphezulu kunye noxinzelelo loxinzelelo kumbindi luya kuhla kancinci de luphele. Nangona kunjalo, njengoko ukupholisa kuqhubeka, ukufuma okungaphezulu kuya kuba ngaphantsi nangaphantsi, kwaye umthamo wokunciphisa uyancipha, okanye uyeke ukucutheka. Ekubeni iqondo lokushisa kwi-core lisephezulu, liya kuqhubeka liyancipha, kwaye ekugqibeleni uxinzelelo loxinzelelo luya kwenziwa kumphezulu we-workpiece, ngelixa i-core iya kuba noxinzelelo lwe-tensile. Nangona kunjalo, ekubeni iqondo lokushisa liphantsi, ukuguqulwa kweplastiki akulula ukwenzeka, ngoko ke olu xinzelelo luya kwanda njengoko ukupholisa kuqhubeka. Iyaqhubeka nokukhula kwaye ekugqibeleni ihlala ngaphakathi kwendawo yokusebenza njengoxinzelelo olushiyekileyo.

Ingabonwa ukuba uxinzelelo lwe-thermal ngexesha lenkqubo yokupholisa ekuqaleni lubangela ukuba i-surface layer yolulwe kwaye i-core igxininiswe, kwaye i-residual stress eseleyo yi-surface layer ukuze ixinzelelwe kwaye ingundoqo yolulwe.

Ukushwankathela, uxinzelelo lwe-thermal oluveliswa ngexesha lokupholisa ukucima lubangelwa ukwahlukana kweqondo lokushisa elinqamlezayo ngexesha lokupholisa. Okukhona umlinganiselo wokupholisa mkhulu kwaye umkhulu umahluko wobushushu obunqamlezayo, kokukhona kukho uxinzelelo lwe-thermal oluveliswayo. Ngaphantsi kweemeko ezifanayo zokupholisa, ukuphakama kobushushu bomsebenzi wokusebenzela, ubukhulu besayizi, buncinci be-thermal conductivity yentsimbi, ubukhulu beqondo lokushisa phakathi kwendawo yokusebenza, kunye noxinzelelo olukhulu lwe-thermal. Ukuba i-workpiece ipholile ngokungafaniyo kwiqondo lokushisa eliphezulu, iya kuphazamiseka kwaye iguqulwe. Ukuba uxinzelelo olukhawulezileyo oluveliswa ngexesha lokupholisa i-workpiece likhulu kunamandla obunzima bezinto eziphathekayo, ukuqhekeka kokucima kuya kwenzeka.

Uxinzelelo lokuguqulwa kwesigaba lubhekiselele kuxinzelelo olubangelwa lixesha elahlukileyo lokuguqulwa kwesigaba kwiindawo ezahlukeneyo zomsebenzi ngexesha lenkqubo yokunyanga ubushushu, eyaziwa ngokuba nguxinzelelo lwezicubu.

Ngexesha lokucima kunye nokupholisa ngokukhawuleza, xa umaleko womphezulu upholile kwi-Ms point, ukuguqulwa kwe-martensitic kwenzeka kwaye kubangela ukwanda kwevolumu. Nangona kunjalo, ngenxa yesithintelo se-core engekabikho utshintsho, i-surface layer ivelisa uxinzelelo olucinezelayo, ngelixa i-core inoxinzelelo lwe-tensile. Xa uxinzelelo lukhulu ngokwaneleyo, luya kubangela ukuguqulwa. Xa i-core ipholile kwi-Ms point, iya kuba nokuguqulwa kwe-martensitic kunye nokwandisa umthamo. Nangona kunjalo, ngenxa yokunyanzeliswa komgangatho womgangatho oguquliweyo kunye neplastiki ephantsi kunye namandla aphezulu, uxinzelelo lwalo lokugqibela oluseleyo luya kuba luhlobo loxinzelelo lomphezulu, kwaye ingundoqo iya phantsi koxinzelelo. Ingabonwa ukuba utshintsho kunye nemeko yokugqibela yoxinzelelo lwenguqu yesigaba ichasene ngokuthe ngqo noxinzelelo lwe-thermal. Ngaphezu koko, ekubeni uxinzelelo lokutshintsha kwesigaba lwenzeka kumaqondo obushushu aphantsi kunye neplastikhi ephantsi, i-deformation inzima ngeli xesha, ngoko ke uxinzelelo lokutshintsha kwesigaba lunokubangela ukuqhekeka kwe-workpiece.

Kukho izinto ezininzi ezichaphazela ubungakanani boxinzelelo lokuguqulwa kwesigaba. Ukukhawuleza kwesantya sokupholisa sentsimbi kuluhlu lobushushu benguqu ye-martensite, ubukhulu bentsimbi yentsimbi, i-thermal conductivity yentsimbi, ubukhulu bomthamo othile we-martensite, ubukhulu becala loxinzelelo lwenguqu. Okukhona iba nkulu. Ukongezelela, uxinzelelo lokuguqulwa kwesigaba lukwanxulumene nokubunjwa kwentsimbi kunye nokuqina kwentsimbi. Ngokomzekelo, i-carbon high high alloy steel inyusa umthamo othile we-martensite ngenxa yekhabhoni ephezulu, okufuneka ikhulise uxinzelelo lokuguqulwa kwesigaba sentsimbi. Nangona kunjalo, njengoko umxholo wekhabhoni usanda, i-Ms point iyancipha, kwaye kukho inani elikhulu le-austenite egciniweyo emva kokucima. Ukwandiswa komthamo wayo kuyancipha kwaye uxinzelelo olushiyekileyo luphantsi.

(2) Ukuguqulwa kwendawo yokusebenza ngexesha lokucima

Ngexesha lokucinywa, kukho iintlobo ezimbini eziphambili zokuguqulwa kwi-workpiece: enye yinguqu kwimilo yejometri ye-workpiece, ebonakaliswa njengokutshintsha kobukhulu kunye nokuma, okubizwa ngokuba yi-warping deformation, ebangelwa ukucima uxinzelelo; enye yi-volume deformation. , ezibonakalisa njengokwandiswa ngokulinganayo okanye ukuchithwa komthamo we-workpiece, okubangelwa utshintsho kwivolumu ethile ngexesha lokutshintsha kwesigaba.

I-Warping deformation ikwabandakanya ukuguqulwa kwemilo kunye nokuguqulwa kokujija. I-twist deformation ibangelwa ikakhulu ngokubekwa okungafanelekanga kwendawo yokusebenza eziko ngexesha lokufudumeza, okanye ukungabikho konyango lokubumba emva kokulungiswa kokuguqulwa ngaphambi kokucima, okanye ukupholisa okungalinganiyo kweendawo ezahlukeneyo zomsebenzi xa i-workpiece ipholile. Le deformation inokuhlalutywa kwaye isonjululwe kwiimeko ezithile. Oku kulandelayo kuxoxa ikakhulu ukuguqulwa komthamo kunye nokuguqulwa kwemilo.

I-1) Izizathu zokucima i-deformation kunye nemithetho yayo eguqukayo

I-Volume deformation ebangelwa ukuguqulwa kwesakhiwo Imo yesakhiwo se-workpiece ngaphambi kokucima ngokuqhelekileyo i-pearlite, oko kukuthi, isakhiwo esixubileyo se-ferrite kunye ne-cementite, kwaye emva kokucima i-martensitic structure. Imiqulu eyahlukeneyo yale zicubu iya kubangela utshintsho lwevolumu ngaphambi nangemva kokucima, okubangela ukuguqulwa. Nangona kunjalo, le deformation ibangela kuphela ukuba i-workpiece yandise kwaye ikhontrakthi ngokulinganayo, ngoko ayitshintshi imilo ye-workpiece.

Ukongeza, okukhona i-martensite kwisakhiwo emva konyango lobushushu, okanye iphezulu isiqulatho sekhabhoni kwi-martensite, kokukhona ukwanda kwayo komthamo, kunye nobuninzi be-austenite egciniweyo, ukwanda komthamo omncinci. Ngoko ke, utshintsho lwevolumu lunokulawulwa ngokulawula umxholo ohambelanayo we-martensite kunye ne-residual martensite ngexesha lonyango lokushisa. Ukuba ilawulwa kakuhle, ivolumu ayiyi kwanda okanye inciphe.

I-deformation ye-shape ebangelwa uxinzelelo lwe-thermal Ukuguqulwa okubangelwa uxinzelelo lwe-thermal lwenzeka kwiindawo zokushisa eziphezulu apho amandla okuvunwa kweengxenye zetsimbi aphantsi, i-plasticity iphezulu, umphezulu upholisa ngokukhawuleza, kwaye umehluko weqondo lokushisa phakathi kwangaphakathi nangaphandle kwendawo yokusebenza iyona inkulu. Ngeli xesha, uxinzelelo lwe-thermal olukhawulezileyo luxinzelelo oluphezulu kunye noxinzelelo oluphambili. Ekubeni iqondo lobushushu eliphambili liphezulu ngeli xesha, amandla esivuno aphantsi kakhulu kunomphezulu, ngoko ke abonakalisa uguquko phantsi kwesenzo soxinzelelo lwe-multi-directional compressive, oko kukuthi, i-cube is spherical in direction. Iintlobo ngeentlobo. Umphumo kukuba enkulu iyancipha, ngelixa incinci iyanda. Ngokomzekelo, i-cylinder ende iyancipha kwindlela yobude kwaye iyanda kwi-diameter direction.

Ukuguqulwa kobume okubangelwa kuxinzelelo lwezicubu Ukuguqulwa okubangelwa luxinzelelo lwezicubu luyenzeka kwangethuba xa uxinzelelo lwezicubu luphezulu. Ngeli xesha, umehluko wokushisa we-cross-section mkhulu, iqondo lokushisa eliphambili liphezulu, lisekho kwi-austenite state, iplastiki ilungile, kwaye amandla esivuno aphantsi. Uxinzelelo lwethishu olukhawulezileyo luxinzelelo loxinzelelo oluphezulu kunye noxinzelelo oluphambili. Ngoko ke, i-deformation ibonakaliswa njengokwandiswa kwengundoqo phantsi kwesenzo soxinzelelo lwe-multi-directional tensile. Isiphumo kukuba phantsi kwesenzo soxinzelelo lwezicubu, icala elikhulu lomsebenzi likhula, ngelixa icala elincinci lifinyeza. Ngokomzekelo, i-deformation ebangelwa uxinzelelo lwezicubu kwi-cylinder ende ubude kunye nokunciphisa ububanzi.

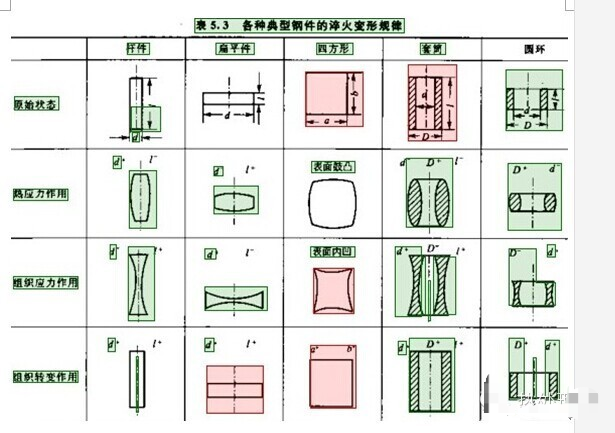

Itheyibhile 5.3 ibonisa imithetho yokucima i-deformation yeendawo ezahlukeneyo zentsimbi eziqhelekileyo.

2) Izinto ezichaphazela ukucima i-deformation

Izinto ezichaphazela i-deformation yokucima ubukhulu becala ukubunjwa kweekhemikhali zensimbi, isakhiwo sokuqala, i-geometry yamacandelo kunye nenkqubo yokunyanga ukushisa.

3) Ukucima iintanda

Ukuqhekeka kwiindawo ikakhulu kwenzeka kwisigaba samva sokucima kunye nokupholisa, oko kukuthi, emva kokuba inguqu ye-martensitic igqityiwe ngokusisiseko okanye emva kokupholisa okupheleleyo, ukusilela kwe-brittle kwenzeka ngenxa yokuba uxinzelelo lwe-tensile kwiindawo ludlula amandla okuqhekeka kwentsimbi. Iintanda zihlala zi-perpendicular ukuya kwicala le-tensile deformation ephezulu, ngoko ke iindlela ezahlukeneyo zokuqhekeka kwiindawo zixhomekeke ikakhulu kwimeko yokusabalalisa uxinzelelo.

Iindidi eziqhelekileyo zokucima iintanda: Ukuqhekeka kwe-Longitudinal (axial) kuveliswa ngokuyinhloko xa uxinzelelo lwe-tangential ludlula amandla okuphuka kwezinto; iintanda ezinqamlezileyo zenziwa xa uxinzelelo olukhulu lwe-axial lwe-tensile olwenziwe kumphezulu ongaphakathi wenxalenye ludlula amandla okuqhawuka kwezinto. Iintanda; iintanda zenethiwekhi zenziwe phantsi kwesenzo soxinzelelo lwe-two-dimensional tensile phezu komhlaba; ukukrazula iintanda zenzeke kumleko obhityileyo oqinileyo, onokuthi wenzeke xa uxinzelelo lutshintsha kabukhali kwaye uxinzelelo olugqithisileyo lusebenza kwicala le-radial. Uhlobo lokuqhekeka.

Iintanda zeLongitudinal nazo zibizwa ngokuba yi-axial cracks. Iintanda zenzeke kowona xinzelelo luphezulu loxinzelelo kufutshane nomphezulu wenxalenye, kwaye zibe nobunzulu obuthile ukuya embindini. Isalathiso sokuqhekeka ngokuqhelekileyo sihambelana ne-axis, kodwa isalathiso sinokutshintsha kwakhona xa kukho uxinzelelo loxinzelelo kwinxalenye okanye xa kukho iziphene zesakhiwo sangaphakathi.

Emva kokuba i-workpiece icinywe ngokupheleleyo, iintanda ze-longitudinal ziyakwazi ukwenzeka. Oku kunxulumene noxinzelelo olukhulu lwetangential kumphezulu wesixhobo sokusebenza esicinyiweyo. Njengoko umxholo wekhabhoni wentsimbi ukhula, ukuthambekela kokwenza ii-longitudinal cracks kwandisa. Intsimbi yekhabhoni ephantsi inomthamo omncinci othile we-martensite kunye noxinzelelo olunamandla lwe-thermal. Kukho uxinzelelo olukhulu olushiyekileyo olucinezelayo kumphezulu, ngoko akulula ukucinywa. Njengoko umxholo wekhabhoni usanda, uxinzelelo lwe-surface compressive luyancipha kwaye uxinzelelo lwesakhiwo luyanda. Kwangaxeshanye, i-peak tensile yoxinzelelo ihambela kumaleko angaphezulu. Ngoko ke, intsimbi yekhabhoni ephezulu ixhomekeke kwiintanda zokucima i-longitudinal xa ishushu.

Ubungakanani bamacandelo buchaphazela ngokuthe ngqo ubungakanani kunye nokusabalalisa uxinzelelo olushiyekileyo, kwaye ukuthambekela kwayo kokuqhawula ukucima kukwahluke. Iintanda zeLongitudinal nazo zenziwe ngokulula ngokucima ngaphakathi koluhlu lwesayizi yecandelo eliyingozi. Ukongeza, ukuvaleka kwezixhobo zentsimbi kudla ngokubangela ukuqhekeka kwe-longitudinal. Ekubeni iindawo ezininzi zetsimbi zenziwe ngokuqengqeleka, i-non-gold inclusions, i-carbides, njl njl kwintsimbi isasazwa kunye ne-deformation direction direction, ebangela ukuba insimbi ibe yi-anisotropic. Ngokomzekelo, ukuba insimbi yensimbi inesakhiwo esifana nebhendi, amandla ayo okuqhekeka okunqamlezayo emva kokucima i-30% ukuya kwi-50% encinci kunokomelela kwe-longitudinal fracture. Ukuba kukho izinto ezifana ne-non-gold inclusions kwintsimbi ebangela uxinzelelo lwexinzelelo, nokuba uxinzelelo lwe-tangential lukhulu kunoxinzelelo lwe-axial, ii-Longitudinal cracks zilula ukwenza phantsi kweemeko eziphantsi zoxinzelelo. Ngenxa yesi sizathu, ukulawulwa okungqongqo kwinqanaba le-non-metallic inclusions kunye noshukela kwintsimbi yinto ebalulekileyo ekukhuseleni ukuqhekeka kokucima.

Iimpawu zokusasazwa koxinzelelo lwangaphakathi lweentanda ezinqamlezileyo kunye nokuqhekeka kwe-arc zezi: umphezulu uphantsi koxinzelelo loxinzelelo. Emva kokushiya umphezulu kumgama othile, uxinzelelo olucinezelayo lutshintshela kuxinzelelo olukhulu loxinzelelo. Ukuqhekeka kwenzeka kwindawo yoxinzelelo lwe-tensile, kwaye ke xa uxinzelelo lwangaphakathi Lusasazeka kumphezulu wenxalenye kuphela ukuba lusasazwa ngokutsha okanye ukunyanzeliswa kwentsimbi kuyanda.

Iintanda ezinqamlezileyo zihlala zisenzeka kwiindawo ezinkulu zeshaft, ezinje ngeerola, iiroyitha zomoya okanye ezinye iindawo zeshaft. Iimpawu zokuqhekeka kukuba zi-perpendicular ukuya kwi-axis direction kwaye ziphule ukusuka ngaphakathi ukuya ngaphandle. Zihlala zibunjwa ngaphambi kokuba ziqiniswe kwaye zibangelwa uxinzelelo lwe-thermal. I-forgings enkulu ihlala ineziphene ze-metallurgical ezifana ne-pores, inclusions, ii-cracks ezifakelwayo kunye namabala amhlophe. Ezi ziphene zisebenza njengendawo yokuqala yokuphuka kunye nokuphuka phantsi kwesenzo soxinzelelo lwe-axial. Ukuqhekeka kwe-arc kubangelwa uxinzelelo lwe-thermal kwaye ngokuqhelekileyo lusasazwa kwi-arc shape kwiindawo apho ubume benxalenye buguquka. Iyenzeka kakhulu ngaphakathi kwendawo yokusebenza okanye kufuphi nemiphetho ebukhali, iigrooves kunye nemingxuma, kwaye isasazwe kwi-arc shape. Xa iinxalenye zetsimbi eziphezulu zekhabhoni ezinobubanzi okanye ubukhulu be-80 ukuya kwi-100 mm okanye ngaphezulu azicinywanga, umphezulu uya kubonisa uxinzelelo oluxinzelelekileyo kwaye iziko liya kubonisa uxinzelelo olunzima. Uxinzelelo, uxinzelelo oluphezulu lwe-tensile lwenzeka kwindawo yokutshintsha ukusuka kuluhlu oluqinileyo ukuya kuluhlu olungaqinanga, kunye nokuqhekeka kwe-arc kwenzeka kule mimandla. Ukongezelela, izinga lokupholisa kwiindawo ezibukhali kunye neekona zikhawuleza kwaye zonke ziyacinywa. Xa utshintshela kwiindawo ezithambileyo, oko kukuthi, kwindawo engaqinanga, ummandla woxinzelelo oluphezulu ubonakala apha, ngoko ke ii-arc cracks zivame ukwenzeka. Izinga lokupholisa kufutshane nomngxuma we-pin, igroove okanye umngxuma osembindini we-workpiece uyacotha, umaleko oqinileyo ohambelanayo ubhityile, kunye noxinzelelo lwe-tensile kufutshane nendawo yenguqu eqinileyo inokubangela ngokulula iintanda ze-arc.

Iintanda zereticular, ezaziwa ngokuba ziintanda zomphezulu, ziintanda ezingaphezulu. Ubunzulu boqhekeko abunzulu, ngokubanzi bujikeleze i-0.01 ~ 1.5mm. Uphawu oluphambili lolu hlobo lokuqhekeka kukuba ulwalathiso olungenasizathu sokuqhekeka alunanto yakwenza nokumila kwenxalenye. Iintanda ezininzi ziqhagamshelwe omnye komnye ukwenza inethiwekhi kwaye zisasazwa ngokubanzi. Xa ubunzulu be-crack bukhulu, obungaphezulu kwe-1 mm, iimpawu zothungelwano ziyanyamalala kwaye zibe zilungelelaniswe ngokungaqhelekanga okanye zisasazwe ngokude. Ukuqhekeka kwenethiwekhi kunxulumene nemeko yoxinzelelo lwe-two-dimensional tensile kumphezulu.

Ikhabhoni ephezulu okanye iinxalenye zetsimbi ze-carburized kunye ne-decarburized layer kwi-surface zilungele ukwenza iintanda zenethiwekhi ngexesha lokucima. Oku kungenxa yokuba umaleko womphezulu unomxholo ophantsi wekhabhoni kunye nevolumu encinci ethile kunomaleko wangaphakathi we-martensite. Ngexesha lokucima, umgangatho we-carbide uphantsi koxinzelelo olunzima. Amacandelo anomaleko we-dephosphorization angasuswanga ngokupheleleyo ngexesha lokucutshungulwa ngoomatshini nawo aya kwenza iintanda zenethiwekhi ngexesha le-high-frequency okanye i-flame surface quenching. Ukuze ugweme ukuqhekeka okunjalo, umgangatho ophezulu wamacandelo kufuneka ulawulwe ngokungqongqo, kwaye i-oxidation welding kufuneka ithintelwe ngexesha lokunyanga ukushisa. Ukongeza, emva kokuba ukufa forging kusetyenziswa ixesha elithile, ukudinwa thermal iintanda ezibonakala imicu okanye uthungelwano emngxunyeni kunye neentanda kwinkqubo yokusila iinxalenye ezicinyiweyo zonke zezi fom.

Ukuqhekeka kweentanda kwenzeka kwindawo emxinwa kakhulu yomgangatho ongaphezulu. Uxinzelelo loxinzelelo lusebenza kwicala le-axial kunye ne-tangential, kwaye uxinzelelo lwenzeka kwicala le-radial. Iintanda zihambelana nomphezulu wenxalenye. Ukuxotyulwa koqweqwe oluqinileyo emva kokucinywa komphezulu kunye neendawo zokungcwatywa kwe-carburizing zipholile zokokuqhekeka okunjalo. Ukwenzeka kwayo kuhambelana nesakhiwo esingalinganiyo kwinqanaba elilukhuni. Ngokomzekelo, emva kokuba i-alloy carburized steel ipholile ngesantya esithile, isakhiwo kwi-carburized layer yile: umaleko wangaphandle we-pearlite ecolekileyo kakhulu + i-carbide, kunye ne-sublayer yi-martensite + i-Residual Austenite, i-maleko yangaphakathi ilungile okanye i-pearlite ecolekileyo kakhulu. Ekubeni ukubunjwa kwevolumu ethile ye-sub-layer martensite yeyona nto inkulu, isiphumo sokunyuswa kwevolumu kukuba uxinzelelo olucinezelayo lusebenza kuluhlu lwe-axial kunye ne-tangential, kwaye uxinzelelo lwe-tensile lwenzeka kwicala le-radial, kwaye ukuguqulwa koxinzelelo lwenzeka ngaphakathi, ukutshintshela kwimeko yoxinzelelo, kunye nokuqhekeka kweentanda Kwenzeka kwiindawo ezinqabileyo kakhulu apho ukuguquka koxinzelelo. Ngokuqhelekileyo, iintanda zihlala ngaphakathi ngokunxuseneyo kumphezulu, kwaye kwiimeko ezinzima zinokubangela ukuxobulwa komhlaba. Ukuba izinga lokupholisa lamacandelo e-carburized likhawuleza okanye lincitshisiwe, isakhiwo se-martensite esifanayo okanye i-ultra-fine pearlite isakhiwo sinokufumaneka kwi-carburized layer, enokuthintela ukwenzeka kweentanda ezinjalo. Ukongeza, ngexesha lokucinywa kwe-frequency ephezulu okanye i-flame surface quenching, umphezulu uhlala ushushu kakhulu kwaye i-inhomogeneity yesakhiwo ecaleni komgangatho oqinileyo unokwenza lula ukuqhekeka komhlaba.

I-Microcracks yahlukile kwiintanda ezine ezikhankanywe ngasentla kuba zibangelwa yi-microstress. Ukuqhekeka kwe-Intergranular ezibonakala emva kokucima, ukufudumeza kunye nokusila kwensimbi ephezulu yekhabhoni okanye i-workpieces ye-carburized, kunye nokuqhekeka okubangelwa ukuvutha kwexesha elifanelekileyo kwamacandelo acinyiweyo, zonke zihambelana nobukho kunye nokwandiswa okulandelayo kwee-microcracks kwintsimbi.

Ii-microcracks kufuneka zihlolwe phantsi kwe-microscope. Ngokuqhelekileyo zenzeke kwimida ye-austenite yasekuqaleni okanye ekudibaneni kwamaphepha e-martensite. Ezinye iintanda zingena kumaphepha emartensite. Uphando lubonisa ukuba ii-microcracks zixhaphake kakhulu kwi-flaky twinned martensite. Isizathu kukuba i-martensite ene-flaky idibanisa enye kwenye xa ikhula ngesantya esiphezulu kwaye yenza uxinzelelo oluphezulu. Nangona kunjalo, i-martensite edibeneyo ngokwayo i-brittle kwaye ayikwazi ukuvelisa i-deformation yePlastiki ikhulula uxinzelelo, ngaloo ndlela ibangela i-microcracks ngokulula. Iinkozo ze-austenite zirhabaxa kwaye ukuchaphazeleka kwe-microcracks kuyanda. Ubukho be-microcracks kwintsimbi buya kunciphisa kakhulu amandla kunye neplastiki yeendawo ezicinyiweyo, ezikhokelela kumonakalo wokuqala (ukwaphuka) kwamacandelo.

Ukuze ugweme i-microcracks kwiindawo zetsimbi eziphezulu zekhabhoni, imilinganiselo enjengokushisa okuphantsi kokucima ukushisa, ukufumana isakhiwo esihle se-martensite, kunye nokunciphisa umxholo wekhabhoni kwi-martensite ingamkelwa. Ukongezelela, ukufudumala ngexesha elifanelekileyo emva kokucima kuyindlela efanelekileyo yokunciphisa uxinzelelo lwangaphakathi. Uvavanyo luye lwabonisa ukuba emva kokufudumala okwaneleyo ngaphezu kwe-200 ° C, i-carbides ehlanjululwe kwiintanda zinefuthe "lokutshisa" iintambo, ezinokunciphisa kakhulu iingozi ze-microcracks.

Oku ngasentla yingxoxo yezizathu kunye neendlela zokuthintela iintanda ngokusekelwe kwipatheni yokusabalalisa ukuqhekeka. Kwimveliso yokwenyani, ukusasazwa kweentanda kuyahluka ngenxa yezinto ezifana nomgangatho wentsimbi, ukumila kwenxalenye, kunye neteknoloji yokucubungula eshushu nabandayo. Ngamanye amaxesha iintanda sele zikhona phambi kokuba unyango lobushushu kunye nokwandisa ngakumbi ngexesha lenkqubo yokucima; ngamanye amaxesha iintlobo ezininzi zeentanda zinokuvela kwindawo enye ngaxeshanye. Kule meko, ngokusekelwe kwiimpawu ze-morphological of crack, uhlalutyo lwe-macroscopic ye-fracture surface, uviwo lwe-metallographic, kwaye xa kuyimfuneko, uhlalutyo lweekhemikhali kunye nezinye iindlela kufuneka zisetyenziswe ukwenza uhlalutyo olubanzi ukusuka kumgangatho wezinto eziphathekayo, ukwakhiwa kombutho ukuya kwizizathu zoxinzelelo lonyango lobushushu ukufumana i-crack. ezona zizathu ziphambili kwaye emva koko zimisele amanyathelo okuthintela asebenzayo.

Uhlalutyo lokuqhekeka kweentanda yindlela ebalulekileyo yokuhlalutya izizathu zokuqhekeka. Nakuphi na ukwaphuka kunesiqalo sokuqhekeka. Ukucima iintanda ngokuqhelekileyo ziqala ukusuka kwindawo yokudibanisa yeentanda ze-radial.

Ukuba imvelaphi yokuqhekeka ikhona kumphezulu wenxalenye, oko kuthetha ukuba ukuqhekeka kubangelwa uxinzelelo olugqithisileyo phezu komhlaba. Ukuba akukho ziphene zesakhiwo ezifana nokufakwa kwi-surface, kodwa kukho izinto zokuxininisa uxinzelelo ezifana namanqaku obunzima obunzima, isikali se-oxide, iikona ezibukhali zeengxenye zetsimbi, okanye iindawo zokuguqulwa kwesakhiwo, ukuqhekeka kunokwenzeka.

Ukuba imvelaphi yokuqhekeka ingaphakathi kwenxalenye, inxulumene neziphene zezinto okanye uxinzelelo lwangaphakathi olushiyekileyo. Umphezulu wokuqhekeka kokucima okuqhelekileyo kungwevu kunye neporcelain entle. Ukuba indawo eqhekekileyo ingwevu emnyama kwaye irhabaxa, ibangelwa kukushisa okugqithisileyo okanye izicubu zokuqala zityebile.

Ngokuqhelekileyo, akufuneki kubekho umbala we-oxidation kwicandelo leglasi le-crack yokucima, kwaye akufanele kubekho i-decarburization ejikeleze ukuqhekeka. Ukuba kukho i-decarburization ejikeleze ukuqhekeka okanye umbala oxidized kwicandelo lokuqhekeka, kubonisa ukuba inxalenye esele ineentanda ngaphambi kokucima, kwaye iintanda zokuqala ziya kwandisa phantsi kweempembelelo zoxinzelelo lonyango lokushisa. Ukuba i-carbides ehlukeneyo kunye ne-inclusions ibonwa kufuphi nokuqhekeka kwenxalenye, ithetha ukuba iintambo zihambelana nokuhlukana okunzima kwe-carbides kwizinto eziluhlaza okanye ubukho bezinto ezifakiwe. Ukuba iintanda zivela kuphela kwiikona ezibukhali okanye ukumila iinxalenye zokuguqulwa kwenxalenye ngaphandle kwesiganeko esingasentla, oko kuthetha ukuba i-crack ibangelwa kuyilo olungekho ngqiqweni lwesakhiwo senxalenye okanye amanyathelo angafanelekanga okuthintela iintanda, okanye uxinzelelo olugqithisileyo lonyango lobushushu.

Ukongeza, iintanda kunyango lobushushu bekhemikhali kunye neendawo zokucima umphezulu zivela ikakhulu kufutshane nomgangatho oqinileyo. Ukuphucula ukwakheka komgangatho oqinileyo kunye nokunciphisa uxinzelelo lonyango lokushisa ziindlela ezibalulekileyo zokuphepha ukuqhekeka komhlaba.

Ixesha lokuposa: May-22-2024