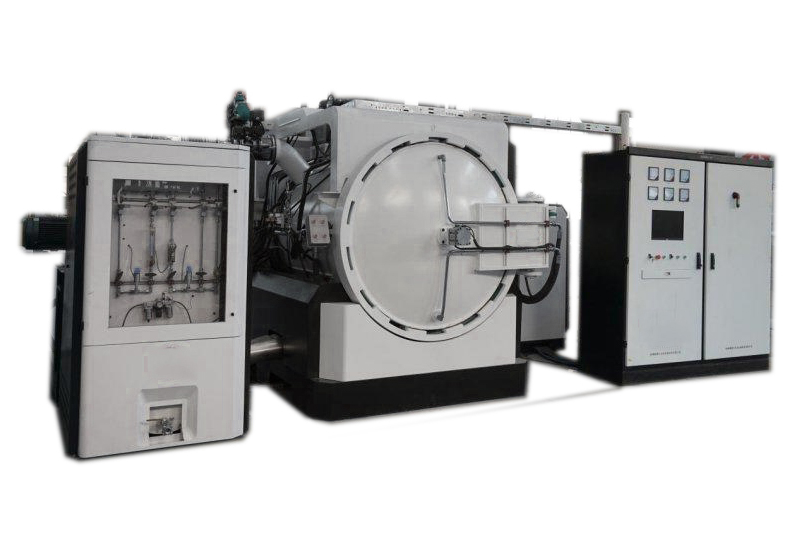

I-vacuum sintering furnace isetyenziswa ikakhulu kwinkqubo yokuntywila yamacandelo e-semiconductor kunye nezixhobo zokulungisa amandla.Inokwenza i-vacuum sintering, i-sintering ekhuselweyo ngegesi kunye ne-sintering eqhelekileyo.Sisixhobo senkqubo yenoveli kuthotho lwezixhobo ezikhethekileyo zesemiconductor.Inombono woyilo lwenoveli, ukusebenza ngokufanelekileyo kunye nesakhiwo esincinci.Iinkqubo ezininzi zokuqukuqela zingagqitywa kwisixhobo esinye.Inokusetyenziswa kwakhona kunyango lwe-vacuum yokushisa, i-vacuum brazing kunye nezinye iinkqubo kwezinye iindawo.

Izakhono eziyimfuneko zokusetyenziswa kwesithando se-vacuum sintering

Isithando somlilo esiphezulu se-vacuum sintering sisetyenziselwa ukwenza i-tungsten crucible kwikhoyili ivelise ubushushu obuphezulu phantsi kokhuseleko lokuzaliswa kwe-hydrogen emva kokupompa i-vacuum kunye nomgaqo wokufudumeza okuphakathi kwe-frequency induction, edluliselwa kumsebenzi ngemitha ye-thermal.Ilungele ukwenza umgubo kunye ne-sintering ye-alloys ye-refractory efana ne-tungsten, i-molybdenum kunye ne-alloys zabo kuphando lwezenzululwazi kunye neeyunithi zoshishino lwezomkhosi.Indawo apho isithando sombane sifakwe khona siya kuhlangabezana neemfuno zokucoceka kwe-vacuum, umoya ojikelezayo uya kucoceka kwaye wome, kwaye kuya kuba neemeko ezintle zomoya.Indawo yokusebenza ayilula ukuphakamisa uthuli, njl.

Izakhono zokusetyenziswa kwemihla ngemihla kwi-vacuum sintering furnece:

1. Khangela ukuba onke amacandelo kunye nezixhobo kwikhabhinethi yolawulo zigqityiwe kwaye zilungile.

2. Ikhabhinethi yokulawula iya kufakwa kwisiseko esihambelanayo kunye nesigxina.

3. Ngokomzobo we-wiring kunye nokubhekisela kumzobo weskimu sombane, qhagamshela isiphaluka esiphambili sangaphandle kunye nesiphaluka sokulawula, kwaye usekelwe ngokuthembekileyo ukuqinisekisa i-wiring echanekileyo.

4. Khangela ukuba indawo eshukumayo yesixhobo sombane kufuneka ihambe ngokukhululekileyo ngaphandle kokugxumeka.

5. Ukuxhatshazwa kwe-insulation akuyi kuba ngaphantsi kwe-2 megohm.

6. Zonke iivalve zesithando somlilo esifunxayo kufuneka zibe kwindawo evaliweyo.

7. Beka isitshixo samandla olawulo kwindawo ecinyiweyo.

8. Jika iqhosha lokulawula uxinzelelo lwemanuwali ngokunxamnye newotshi.

9. Beka iqhosha le-alam kwindawo evulekileyo.

10. Gqibezela ukudityaniswa kwamanzi okupholisa okujikelezayo kwesixhobo ngokwesicwangciso.Kucetyiswa ukuba umsebenzisi aqhagamshele amanye amanzi okulinda (amanzi epompo akhoyo) kwindawo yokungena kunye nokuphuma kombhobho wesixhobo ukuthintela umsesane wokutywina ekutshisweni ngenxa yokusilela kwamanzi ajikelezayo okanye ukusilela kombane.

Ixesha lokuposa: May-07-2022