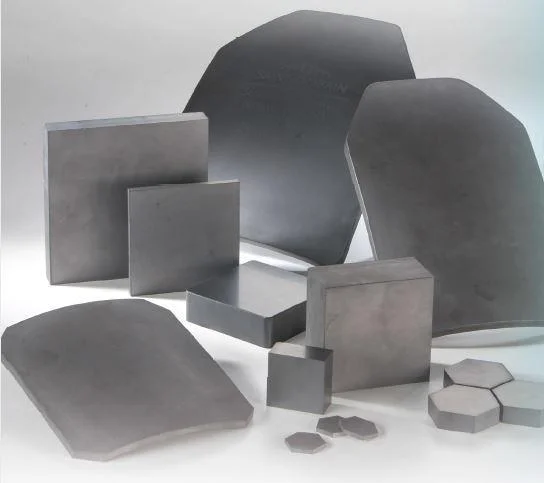

I-Silicon carbide ceramics inamandla obushushu obuphezulu, ukumelana nobushushu obuphezulu be-oxidation, ukumelana nokunxiba kakuhle, ukuzinza okuhle kwe-thermal, i-coefficient encinci yokwandiswa kwe-thermal, i-thermal conductivity ephezulu, ukuqina okuphezulu, ukuxhathisa ubushushu, ukuxhathisa ukubola kweekhemikhali kunye nezinye iipropathi ezigqwesileyo. Isetyenziswe ngokubanzi kwimoto, kumatshini, ukhuseleko lokusingqongileyo, itekhnoloji ye-aerospace, ulwazi lwe-elektroniki, amandla kunye namanye amasimi, kwaye iye yaba yi-ceramic yolwakhiwo engenakubuyiselwa kunye nokusebenza okugqwesileyo kumashishini amaninzi. Ngoku mandikubonise!

Sintering ngaphandle koxinzelelo

I-Sintering engenaxinzelelo ithathwa njengeyona ndlela ithembisayo ye-SiC sintering. Ngokweendlela ezahlukeneyo zokuntywila, i-sintering engenaxinzelelo inokwahlulwa ibe yi-slid-phase sintering kunye ne-liquid-phase sintering. Ngokusebenzisa i-ultra-fine β- Isixa esifanelekileyo se-B kunye ne-C (i-oxygen content ngaphantsi kwe-2%) yongezwa kwi-SiC powder ngexesha elifanayo, kunye ne-s. Iproehazka yacwiliswa kumzimba we-SiC sintered kunye noxinano olungaphezulu kwe-98% ngo-2020 ℃. A. Mulla et al. I-Al2O3 kunye ne-Y2O3 zisetyenziswe njengezongezo kunye ne-sintered kwi-1850-1950 ℃ ye-0.5 μ m β-SiC (i-particle surface iqukethe inani elincinci le-SiO2). Ubuninzi obunxulumene neekeramics ze-SiC ezifunyenweyo zikhulu kune-95% yoxinaniso lwethiyori, kwaye ubungakanani beenkozo buncinci kunye nobukhulu obuphakathi. Ziyi-1.5 microns.

I-Hot press sintering

I-SiC ecocekileyo inokufakwa kuphela ngokudibeneyo kubushushu obuphezulu kakhulu ngaphandle kokongeza izongezo, abantu abaninzi baphumeza inkqubo yokucinezela eshushu ye-SiC. Kukho iingxelo ezininzi malunga nokucofa okushushu kwe-SiC ngokongeza izixhobo zokuncedisa. Alliegro et al. Ufunde isiphumo se-boron, i-aluminiyam, i-nickel, isinyithi, i-chromium kunye nezinye izongezo zentsimbi kwi-SiC densification. Iziphumo zibonisa ukuba i-aluminiyam kunye nentsimbi zezona zongezo zisebenzayo ukukhuthaza i-SiC eshushu yokucinezela i-sintering. I-FFlange yafunda umphumo wokongeza inani elahlukileyo le-Al2O3 kwiipropati ze-SiC ecinezelekileyo. Kucatshangelwa ukuba ukuxinana kwe-SiC ecinezelweyo eshushu kuhambelana nendlela yokuchithwa kunye nemvula. Nangona kunjalo, inkqubo yokushicilela eshushu inokuvelisa kuphela iinxalenye zeSiC ezinemilo elula. Ubuninzi beemveliso eziveliswa yinkqubo yexesha elilodwa lokutshisa i-hot sintering encinci kakhulu, engabangeli ukuveliswa kwemveliso.

I-isostatic eshushu yokucofa sintering

Ukuze unqobe ukusilela kwenkqubo ye-sintering yendabuko, uhlobo lwe-B kunye nohlobo lwe-C lwasetyenziswa njengezongezo kunye ne-isostatic eshushu ye-sintering iteknoloji yamkelwa. Kwi-1900 ° C, ii-ceramics ze-crystalline ezintle ezinobuninzi obungaphezulu kwe-98 zifunyenwe, kwaye amandla okugoba kwiqondo lokushisa elingaphakathi angafikelela kwi-600 MPa. Nangona i-isostatic eshushu yokucinezela i-sintering inokuvelisa iimveliso zesigaba esishinyeneyo ezinemilo entsonkothileyo kunye nepropathi elungileyo yomatshini, i-sintering kufuneka itywinwe, ekunzima ukuyifezekisa imveliso yeshishini.

Reaction sintering

I-Reaction sintered silicon carbide, ekwaziwa ngokuba yi-self bonded silicon carbide, ibhekisa kwinkqubo apho i-porous billet isabela ngerhasi okanye isigaba solwelo ukuphucula umgangatho webillet, ukunciphisa i-porosity, kunye neemveliso ezigqityiweyo ze-sinter ngamandla athile kunye nokuchaneka komda. thatha i-α-SiC powder kunye negraphite zixutywe kumlinganiselo othile kwaye zifudunyezwe malunga ne-1650 ℃ ukwenza i-square billet. Ngelo xesha, ingena okanye ingena kwi-billet nge-Si ye-gaseous kwaye iphendule nge-graphite ukwenza i-β-SiC, idibaniswe kunye neengqungquthela ezikhoyo ze-α-SiC. Xa i-Si ifakwe ngokupheleleyo, i-reaction sintered body enoxinano olupheleleyo kunye nobukhulu obungancitshiyo bunokufumaneka. Xa kuthelekiswa nezinye iinkqubo sintering, utshintsho ubungakanani reaction sintering kwinkqubo densification incinci, kwaye iimveliso ezinobungakanani obuchanekileyo zingalungiswa. Nangona kunjalo, ubukho besixa esikhulu se-SiC kumzimba osikiweyo kwenza ukuba iipropathi zobushushu obuphezulu bokusabela kwi-sintered SiC ceramics zibe mandundu.

Ixesha lokuposa: Jun-08-2022