1. Ukuba nesibindi

Kunzima ukudibanisa i-ceramic kunye ne-ceramic, i-ceramic kunye nezixhobo zetsimbi.Uninzi lwesolder lwenza ibhola kumphezulu we-ceramic, kunye nokumanzisa okuncinci okanye akukho.Intsimbi yokuzalisa isinyithi enokumanzisa i-ceramics ilula ukwenza iintlobo ezahlukeneyo ze-brittle compounds (ezifana ne-carbides, i-silicides kunye ne-ternary okanye i-multivariate compounds) kwi-interface edibeneyo ngexesha lokugcoba.Ubukho balezi zixhobo buchaphazela iimpawu zemishini yokudibanisa.Ukongezelela, ngenxa yokwahlukana okukhulu kwee-coefficients zokwandiswa kwe-thermal phakathi kwe-ceramic, isinyithi kunye ne-solder, kuya kubakho uxinzelelo oluseleyo kwi-joint emva kokuba ubushushu bokushisa bupholile kwiqondo lokushisa, elinokubangela ukuqhekeka ngokubambisana.

Ukumanzi kwe-solder kwi-ceramic surface kunokuphuculwa ngokufaka izinto ezisebenzayo zetsimbi kwi-solder eqhelekileyo;Ukushisa okuphantsi kunye nexesha elifutshane lokuqhawula kunokunciphisa umphumo we-interface reaction;Uxinzelelo lwe-thermal yokudibanisa lunokuncitshiswa ngokuyila ifom edibeneyo efanelekileyo kunye nokusebenzisa isinyithi esisodwa okanye i-multi-layer njengoluhlu oluphakathi.

2. Solder

I-Ceramic kunye nesinyithi zivame ukudibaniswa kwi-vacuum furnace okanye i-hydrogen kunye ne-argon furnace.Ukongeza kwiimpawu eziqhelekileyo, isinyithi sokuzalisa i-vacuum yezixhobo zombane kufuneka zibe neemfuno ezizodwa.Ngokomzekelo, i-solder ayifanele iqulethe izinto ezivelisa uxinzelelo oluphezulu lomphunga, ukwenzela ukuba ungabangeli ukuvuza kwe-dielectric kunye ne-cathode poisoning yezixhobo.Ngokuqhelekileyo kucacisiwe ukuba xa isixhobo sisebenza, uxinzelelo lomphunga lwesolder aluyi kudlula i-10-3pa, kwaye ukungcola okuphezulu komphunga okuqulethwe akusayi kudlula i-0.002% ~ 0.005%;I-w (o) ye-solder ayiyi kuba ngaphezu kwe-0.001%, ukuze kuthintelwe umphunga wamanzi owenziwe ngexesha lokubrawuza kwi-hydrogen, enokubangela ukuchaphaza kwesinyithi esinyibilikisiweyo sesolder;Ukongeza, i-solder kufuneka icoceke kwaye ingabi nama-oxide angaphezulu.

Xa ubhobhoza emva kwe-ceramic metallization, ubhedu, isiseko, ubhedu lwesilivere, ubhedu lwegolide kunye nezinye i-alloy brazing filler metals zingasetyenziswa.

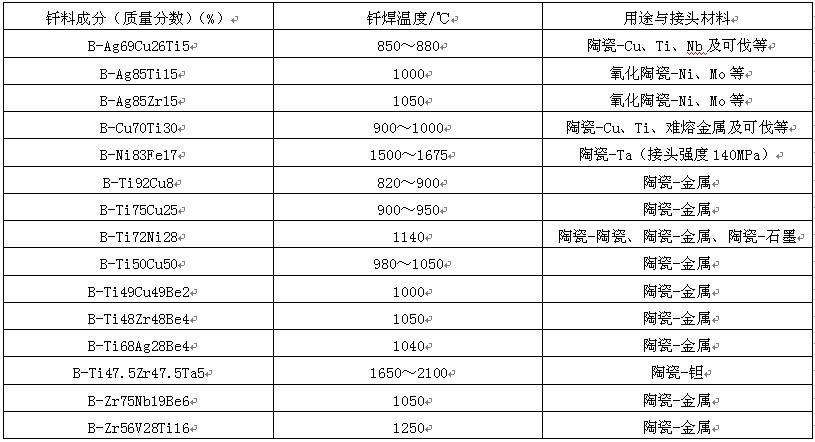

Ukubethelwa ngokuthe ngqo kwee-ceramics kunye nesinyithi, i-brazing filler metals equkethe izinto ezisebenzayo i-Ti kunye ne-Zr iya kukhethwa.Iintsimbi zokuzalisa ibhinari ubukhulu becala ziyi-Ti Cu kunye ne-Ti Ni, enokusetyenziswa kwi-1100 ℃.Phakathi kwe-ternary solder, i-Ag Cu Ti (W) (TI) yeyona solder isetyenziswa ngokuqhelekileyo, enokuthi isetyenziselwe ukubethelwa ngokuthe ngqo kweekeramics ezahlukeneyo kunye neentsimbi.I-ternary filler metal ingasetyenziswa ngefoyile, ipowder okanye iAg Cu eutectic filler metal eneTi powder.I-B-ti49be2 i-brazing filler metal inokumelana ne-corrosion efanayo kwintsimbi engenasici kunye noxinzelelo oluphantsi lomphunga.Inokukhethwa ngokukhethekileyo kwiindawo zokutywinwa kwe-vacuum kunye ne-oxidation kunye nokuchasana nokuvuza.Kwi-ti-v-cr solder, iqondo lokushisa elinyibilikayo lisezantsi (1620 ℃) xa i-w (V) i-30%, kwaye ukongezwa kwe-Cr kunokunciphisa ngokufanelekileyo uluhlu lweqondo lokushisa.I-B-ti47.5ta5 i-solder ngaphandle kwe-Cr isetyenziselwe ukubethelwa ngokuthe ngqo kwe-alumina kunye ne-magnesium oxide, kwaye i-joint yayo inokusebenza kwiqondo lokushisa elingu-1000 ℃.Itheyibhile ye-14 ibonisa i-flux esebenzayo yokudibanisa ngokuthe ngqo phakathi kwe-ceramic kunye nesinyithi.

Itheyibhile ye-14 esebenzayo yokuqhafaza isinyithi sesinyithi se-ceramic kunye nesinyithi

2. Iteknoloji yokubrawuza

Iiseramikhi ezenziwe ngentsimbi zangaphambili zinokugaywa kwirhasi ye-inert yococeko oluphezulu, i-hydrogen okanye i-vacuum bume.I-vacuum brazing isetyenziselwa ukunyanyiswa ngokuthe ngqo kweeseramics ngaphandle kwe-metallization.

(1) Inkqubo yokubrawuza jikelele inkqubo yokubrawuza yendalo yonke yeceramic kunye nentsimbi inokwahlulwa ibe ziinkqubo ezisixhenxe: ukucocwa komphezulu, ukugquma intlama, i-ceramic surface metallization, i-nickel plating, ibrazing kunye nokuhlolwa kwe-post weld.

Injongo yokucoca umphezulu kukususa i-oil stain, i-sweat stain kunye nefilimu ye-oxide phezu kwesiseko sesinyithi.Iingxenye zetsimbi kunye ne-solder ziya kuhlanjululwa kuqala, ngoko ifilimu ye-oxide iya kususwa nge-asidi okanye i-alkali yokuhlamba, ihlanjwe ngamanzi ahambayo kwaye yomiswe.Amacandelo aneemfuno eziphezulu kufuneka aphathwe ngokushushu kwi-vacuum furnace okanye i-hydrogen furnace (indlela ye-ion bombardment ingasetyenziswa) kwiqondo lokushisa elifanelekileyo kunye nexesha lokucoca umphezulu weendawo.Amalungu ahlambulukileyo akayi kuqhagamshelana nezinto ezinamafutha okanye izandla ezingenanto.Ziya kufakwa ngokukhawuleza kwinkqubo elandelayo okanye kwindawo yokomisa.Aziyi kuboniswa emoyeni ixesha elide.Amalungu e-Ceramic aya kucocwa nge-acetone kunye ne-ultrasonic, ahlanjwe ngamanzi ahambayo, kwaye ekugqibeleni abiliswe kabini ngamanzi adibeneyo kwi-15min ngexesha ngalinye.

I-Coating yokunamathisela yinkqubo ebalulekileyo ye-ceramic metallization.Ngexesha lokugquma, isetyenziswe kwi-ceramic surface ukuba ifakwe i-metallized nge-brush okanye umatshini wokunamathisela.Ubungqingqwa bokugquma buqhele ukuba yi-30 ~ 60mm.I-paste ilungiswa ngokubanzi kwi-powder yensimbi ecocekileyo (ngamanye amaxesha i-oxide yensimbi efanelekileyo yongezwa) kunye nobukhulu be-particle malunga ne-1 ~ 5um kunye ne-organic adhesive.

Amalungu e-ceramic acangcisiweyo athunyelwa kwisithando somlilo se-hydrogen kwaye afakwe kwi-hydrogen emanzi okanye i-ammonia eqhekekileyo kwi-1300 ~ 1500 ℃ ye-30 ~ 60min.Kwiindawo ze-ceramic ezigqunywe ngee-hydrides, ziya kufudunyezwa malunga ne-900 ℃ ukubola i-hydrides kwaye zisabele ngentsimbi ecocekileyo okanye i-titanium (okanye i-zirconium) eseleyo kumphezulu we-ceramic ukufumana i-coat yesinyithi kwindawo ye-ceramic.

Kumaleko we-Metalized Metal, ukwenzela ukuba ubemanzi ngesolder, umaleko we-nickel we-1.4 ~ 5um kufuneka ufakwe i-electroplated okanye ugqunywe ngomgubo we-nickel.Ukuba iqondo lobushushu lokubrawuza lingaphantsi kwe-1000 ℃, umaleko we-nickel kufuneka utshiswe ngaphambili kwiziko le-hydrogen.Ubushushu be-sintering kunye nexesha yi-1000 ℃ /15 ~ 20min.

I-ceramics ephathwayo zizinto zetsimbi, eziza kuhlanganiswa ngokupheleleyo kunye nentsimbi engenasici okanye igraphite kunye ne-ceramic molds.I-Solder iya kufakwa kwiindawo ezidibeneyo, kwaye i-workpiece iya kugcinwa icocekile kulo lonke umsebenzi, kwaye ayiyi kuchukunyiswa ngezandla ezingenanto.

Ukutshisa kuya kwenziwa kwi-argon, i-hydrogen okanye i-vacuum furnace.Ukushisa okutshisayo kuxhomekeke kwintsimbi yokuzalisa i-brazing.Ukuthintela ukuqhekeka kwamalungu e-ceramic, isantya sokupholisa asiyi kukhawuleza kakhulu.Ukongeza, i-brazing inokusebenzisa uxinzelelo oluthile (malunga ne-0.49 ~ 0.98mpa).

Ukongeza ekuhlolweni komgangatho womphezulu, iiwelds zebrazed nazo ziya kuba phantsi komothuko we-thermal kunye nokuhlolwa kwepropathi yomatshini.Iindawo zokutywina zezixhobo zevacuum kufuneka kwakhona zibe phantsi kovavanyo lokuvuza ngokwemigaqo efanelekileyo.

(2) Ukunyathela ngokuthe ngqo xa ubhobhoza ngokuthe ngqo (indlela yesinyithi esebenzayo), okokuqala ucoce umphezulu we-ceramic kunye ne-weldments yensimbi, uze udibanise.Ukuze ugweme ukuqhekeka okubangelwa yi-coefficients yokwandiswa kwe-thermal eyahlukeneyo yezinto zecandelo, i-buffer layer (enye okanye ngaphezulu kweelayiti zentsimbi) inokujikelezwa phakathi kwe-weldments.Intsimbi yokuzalisa intsimbi iya kubotshwa phakathi kweewelds ezimbini okanye ibekwe kwindawo apho umsantsa uzaliswe yintsimbi yokuqhafaza kangangoko kunokwenzeka, emva koko ukugada kuya kuqhutywa njengokuvacuum okuqhelekileyo.

Ukuba i-solder ye-Ag Cu Ti isetyenziselwa ukubethelwa ngokuthe ngqo, indlela yokugcoba i-vacuum iya kwamkelwa.Xa i-vacuum degree kwisithando somlilo ifikelela kwi-2.7 × Qala ukufudumeza kwi-10-3pa, kwaye ukushisa kunokunyuka ngokukhawuleza ngeli xesha;Xa iqondo lokushisa lisondele kwindawo yokunyibilika kwe-solder, iqondo lokushisa kufuneka liphakanyiswe kancinci ukwenza ubushushu bazo zonke iindawo ze-weldment zifane;Xa i-solder inyibilika, iqondo lobushushu liya kunyuswa ngokukhawuleza kwiqondo lokushisa, kwaye ixesha lokubamba liya kuba yi-3 ~ 5min;Ngexesha lokupholisa, iyakupholiswa kancinane phambi kwe-700 ℃, kwaye inokupholiswa ngokwendalo ngesithando somlilo emva kwe-700 ℃.

Xa i-solder ye-Ti Cu isebenze ngokuthe ngqo, ifom ye-solder inokuba yi-Cu foil kunye ne-Ti powder okanye iinxalenye ze-Cu kunye ne-Ti foil, okanye umphezulu we-ceramic unokufakwa nge-Ti powder kunye ne-Cu foil.Ngaphambi kokutshisa, zonke iindawo zetsimbi ziya kuchithwa nge-vacuum.Ubushushu bokukhupha umoya we-oksijini yobhedu olungenayo i-750 ~ 800 ℃, kunye ne-Ti, Nb, Ta, njl.njl. iya kukhutshwa kwi-900 ℃ nge-15min.Ngeli xesha, idigri ye-vacuum ayiyi kuba ngaphantsi kwe-6.7 × 10-3Pa. Ngexesha lokuqhaqha, hlanganisa amacandelo afakwe kwi-welded kwi-fixture, uwafudumeze kwisithando somlilo ukuya kwi-900 ~ 1120 ℃, kwaye ixesha lokubamba li-2 ~ 5min.Ngethuba lenkqubo yonke yokuqhaqha, idigri ye-vacuum ayiyi kuba ngaphantsi kwe-6.7 × 10-3Pa.

Inkqubo yokuqhafaza ye-Ti Ni indlela ifana nendlela ye-Ti Cu, kunye nokushisa okutshisayo yi-900 ± 10 ℃.

(3) I-oxide brazing indlela ye-oxide ye-oxid brazing yindlela yokuqonda uxhulumaniso oluthembekileyo ngokusebenzisa isigaba seglasi esenziwe ngokunyibilika kwe-oxide solder ukuba ingene kwiiseramics kwaye imanzise umphezulu wesinyithi.Iyakwazi ukudibanisa i-ceramics kunye neekeramics kunye neeramics ngeentsimbi.Iintsimbi zokuzalisa i-oxide brazing zenziwa ikakhulu yiAl2O3, Cao, Bao kunye neMgO.Ngokudibanisa i-B2O3, i-Y2O3 kunye ne-ta2o3, iintsimbi zokuzalisa i-brazing ezineendawo ezahlukeneyo zokunyibilika kunye ne-coefficients yokwandisa i-linear inokufumaneka.Ukongeza, i-fluoride brazing filler metals kunye ne-CaF2 kunye ne-NaF njengezona zinto ziphambili zinokusetyenziselwa ukudibanisa i-ceramics kunye nesinyithi ukufumana amajoyina anamandla aphezulu kunye nokumelana nobushushu obuphezulu.

Ixesha lokuposa: Jun-13-2022