1. Izinto zokubrasha

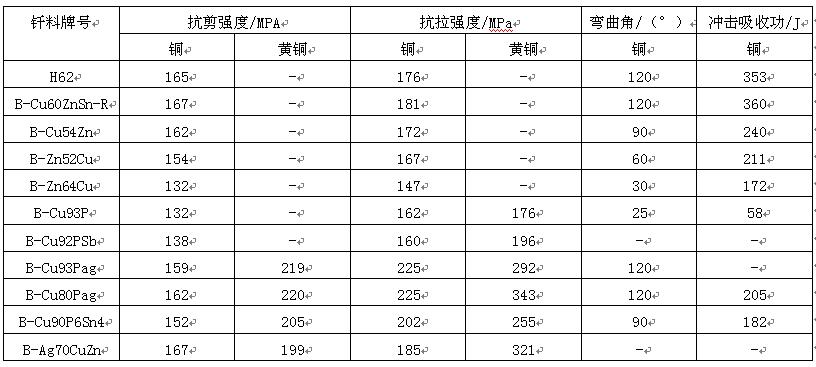

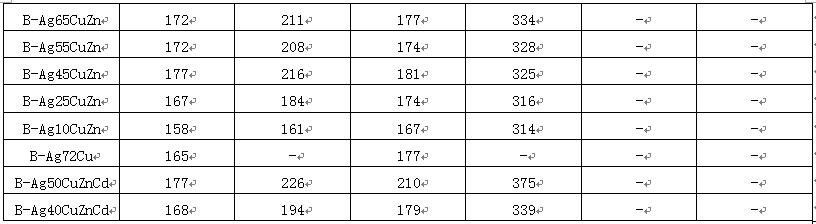

(1) Amandla okudityaniswa kwee-solder ezininzi ezidla ngokusetyenziswa kubhedu kunye nobhedu oluboniswa kwitheyibhile ye-10.

Itheyibhile ye-10 yamandla obhedu kunye nobhedu lwebrazed joints

Xa ubhobhoza ubhedu nge-tin lead solder, i-non-corrosive brazing flux efana ne-rosin alcohol solution okanye i-rosin esebenzayo kunye ne-zncl2 + nh4cl isisombululo samanzi sinokukhethwa.Le yokugqibela ingasetyenziselwa ubhedu lokubhengeza, ubhedu kunye ne-beryllium yobhedu.Xa ubhobhoza ubhedu lwe-aluminium, ubhedu lwe-aluminium kunye nobhedu lwe-silicon, i-brazing flux ingaba yi-zinc chloride hydrochloric acid isisombululo.Xa ubhengeza ubhedu olumhlophe lwe-manganese, i-ejenti yokutofa ingaba isisombululo se-phosphoric acid.Isisombululo samanzi se-zinc chloride sinokusetyenziswa njenge-flux xa ibrawuza nge-lead esekelwe kwi-filler metal, kunye ne-fs205 flux ingasetyenziswa xa ubhobhoza nge-cadmium based filler metal.

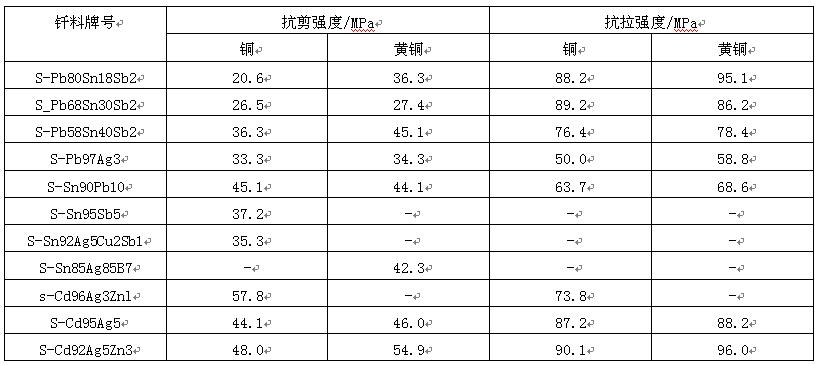

2I-solder esekelwe kwisilivere yeyona nto isetyenziswa kakhulu kwi-solder enzima ngenxa yendawo yayo ephakathi yokunyibilika, i-processability elungileyo, iipropati ezilungileyo zoomatshini, umbane kunye ne-thermal conductivity.Kwisixhobo somsebenzi esifuna ukuhanjiswa okuphezulu, i-b-ag70cuzn solder enomxholo wesilivere ephezulu iya kukhethwa.Ukulungiswa kwevacuum okanye ukubrawuza kwisithando somoya esikhuselayo, i-b-ag50cu, i-b-ag60cusn kunye nezinye izinto zokubrawuza ngaphandle kwezinto eziguquguqukayo ziya kukhethwa.Iintsimbi zokuzalisa i-brazing ezinomxholo wesilivere ophantsi zixabiso eliphantsi, zineqondo lobushushu obuphezulu bokubrawuza kunye nokuqina okulambathayo kwamalungu adityanisiweyo.Ngokuqhelekileyo zisetyenziselwa ubhedu kunye ne-alloys yobhedu kunye neemfuno eziphantsi.I-copper phosphorus kunye ne-copper phosphorus yesilivere ye-brazing filler metals ingasetyenziselwa kuphela ukuxutywa kobhedu kunye ne-alloys zayo zobhedu.Phakathi kwabo, i-b-cu93p ine-fluidity efanelekileyo kwaye isetyenziselwa ukubethelwa kwamalungu angekho phantsi komthwalo wempembelelo kwi-Electromechanical, isixhobo kunye namashishini okuvelisa.Esona sikhewu sifanelekileyo ngu-0.003 ~ 0.005mm.Isinyithi se-phosphorus yesilivere yobhedu yokusikwa kwesinyithi (efana ne-b-cu70pag) inokuqina okungcono kunye nokuhanjiswa kunesinyithi sobhedu se-phosphorus brazing filler metals.Zisetyenziselwa ikakhulu ukudibanisa kombane kunye neemfuno eziphezulu ze-conductivity.Itheyibhile ye-11 ibonisa iipropati ezidibeneyo zezinto ezininzi eziqhelekileyo zokubhobhoza ezisetyenziselwa ukubethelwa kobhedu kunye nobhedu.

Itheyibhile ye-11 yeempawu zobhedu kunye nobhedu oluxutywe ngebrazed

Ixesha lokuposa: Jun-13-2022