1. Solder

Zonke iintlobo zee-solder ezinobushushu obungaphantsi kwe-3000 ℃ zingasetyenziselwa ukubrawuza kwe-W, kunye ne-copper okanye isilivere esekelwe kwii-solders zingasetyenziselwa amacandelo anobushushu obungaphantsi kwe-400 ℃; Igolide esekwe, i-manganese esekwe, i-manganese esekwe, i-palladium esekwe okanye i-drill based filler metal idla ngokusetyenziselwa amacandelo asetyenziswa phakathi kwe-400 ℃ kunye ne-900 ℃; Kumalungu asetyenziswe ngaphezulu kwe-1000 ℃, iintsimbi ezisulungekileyo ezifana ne-Nb, Ta, Ni, Pt, PD kunye ne-Mo zisetyenziswa kakhulu. Ubushushu obusebenzayo bezinto ezixutywe ngeplatinam base solder bufikelele kwi-2150 ℃. Ukuba unyango lwe-diffusion lwe-1080 ℃ lwenziwa emva kokuqhaqha, ubushushu obuphezulu bokusebenza bunokufikelela kwi-3038 ℃.

Uninzi lwee-solders ezisetyenziselwa ukubrawuza w zingasetyenziselwa ukubethelwa kwe-Mo, kunye ne-copper okanye isilivere esekelwe kwii-solders zingasetyenziselwa i-Mo components ezisebenza ngaphantsi kwe-400 ℃; Kwizixhobo zombane kunye neendawo ezingezizo ezakhiweyo ezisebenza kwi-400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni okanye Cu Ni solders zingasetyenziswa; I-Titanium esekwe okanye ezinye iintsimbi ezisulungekileyo zokuzalisa isinyithi ezineendawo eziphezulu zokunyibilika zingasetyenziselwa amacandelo asebenza kumaqondo obushushu aphezulu. Kufuneka kuqatshelwe ukuba i-manganese esekelwe, i-cobalt esekelwe kunye ne-nickel esekelwe kwi-filler metals ngokuqhelekileyo ayikhuthazwa ukuphepha ukubunjwa kwe-brittle intermetallic compounds kwi-brazing joints.

Xa amacandelo e-TA okanye e-Nb asetyenziswa ngaphantsi kwe-1000 ℃, i-copper based based, i-manganese esekelwe, i-cobalt esekelwe, i-titanium esekelwe, i-nickel esekelwe, i-gold based based and palladium based injections can be selected, kubandakanywa i-Cu Au, i-Au Ni, i-PD Ni kunye ne-Pt Au_ Ni kunye ne-Cu Sn solders zinokumanzi kakuhle kwi-TA kunye ne-Nb, i-brazing edibeneyo yokubumba kunye nokwenza i-brazing ephezulu. Njengoko iintsimbi ezisekwe kwisilivere zikholisa ukwenza iintsimbi zokubrawuza zibe brittle, kufuneka zithintelwe kangangoko kunokwenzeka. Kwizinto ezisetyenziswa phakathi kwe-1000 ℃ kunye ne-1300 ℃, iintsimbi ezicocekileyo i-Ti, V, Zr okanye i-alloys esekwe kwezi zinyithi ezenza okuqinileyo okungapheliyo kunye nolwelo kunye nazo ziya kukhethwa njengesinyithi sokuqhafaza. Xa ubushushu benkonzo buphezulu, isinyithi sokuzalisa esine-HF sinokukhethwa.

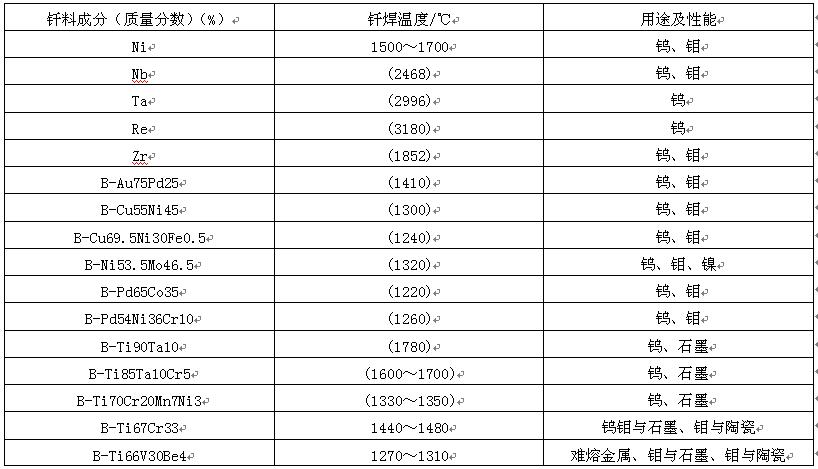

W. Jonga itheyibhile ye-13 yesinyithi sokuzalisa i-Mo, i-Ta kunye ne-Nb kwiqondo lokushisa eliphezulu.

Itheyibhile ye-13 yentsimbi yokuzalisa i-brazing yokubeka ubushushu obuphezulu besinyithi esichasayo

Ngaphambi kokuqhaqha, kufuneka ukuba ususe ngokucophelela i-oxide ebusweni bentsimbi ephikisayo. Ukugaya oomatshini, ukuqhushumba kwesanti, ukucocwa kwe-ultrasonic okanye ukucocwa kweekhemikhali kungasetyenziswa. Ukutshisa kuya kwenziwa ngokukhawuleza emva kwenkqubo yokucoca.

Ngenxa ye-brittleness engokwemvelo ye-W, iinxalenye ze-w ziya kusingathwa ngononophelo kwi-dissembly yecandelo lokusebenza ukuphepha ukwaphuka. Ukuze kuthintelwe ukubunjwa kwe-brittle tungsten carbide, ukudibanisa ngokuthe ngqo phakathi kwe-W kunye ne-graphite kufuneka kugwenywe. Uxinzelelo ngenxa ye-welding yangaphambili okanye i-welding iya kupheliswa phambi kwe-welding. I-W ilula kakhulu i-oxidize xa ubushushu buphakama. Idigri yevacuum iya kuba phezulu ngokwaneleyo ngexesha lokubrawuza. Xa i-brazing iqhutyelwa ngaphakathi kwiqondo lokushisa kwe-1000 ~ 1400 ℃, i-degree ye-vacuum ayiyi kuba ngaphantsi kwe-8 × 10-3Pa. Ukuze kuphuculwe ukufudumala kweqondo lokushisa kunye nokushisa kwenkonzo yokubambisana, inkqubo yokuqhafaza inokudibaniswa kunye nonyango lwe-diffusion emva kwe-welding. Umzekelo, i-b-ni68cr20si10fel solder isetyenziselwa ukujongisa i-W ku-1180 ℃. Emva kokunyangwa kathathu kwe-1070 ℃ / 4h, 1200 ℃ / 3.5h kunye ne-1300 ℃ / 2h emva kwe-welding, ubushushu benkonzo ye-brazed joint inokufikelela ngaphezulu kwe-2200 ℃.

I-coefficient encinci yokwandiswa kwe-thermal kufuneka ithathelwe ingqalelo xa uhlanganisa i-brazed joint of Mo, kwaye i-gap edibeneyo kufuneka ibe phakathi koluhlu lwe-0.05 ~ 0.13MM. Ukuba i-fixture isetyenzisiwe, khetha into ene-coefficient encinci yokwandiswa kwe-thermal. I-Mo recrystallization iyenzeka xa i-flame brazing, isithando somlilo esilawulwayo, i-vacuum furnace, i-furnace induction kunye nokufudumeza ukuchasana kudlula iqondo lokushisa okanye i-recrystallization iyancipha ngenxa yokusabalalisa izinto ze-solder. Ngoko ke, xa iqondo lokushisa elivuthayo lisondele kwiqondo lokushisa le-recrystallization, lifutshane ixesha lokuqhayisa, lingcono. Xa ubhobhoza ngaphezu kobushushu be-recrystallization ye-Mo, ixesha lokuqhaqha kunye nesantya sokupholisa kufuneka lilawulwe ukuphepha ukuqhekeka okubangelwa ukupholisa ngokukhawuleza. Xa kusetyenziswa i-oxyacetylene flame brazing, kulungele ukusebenzisa i-mixed flux, oko kukuthi, i-borate ye-industrial okanye i-silver brazing flux kunye ne-high-temperature flux ene-calcium fluoride, enokufumana ukhuseleko oluhle. Indlela yokuqala yokwambathisa umaleko wesilivere eguquguqukayo eguquguqukayo kumphezulu we-Mo, kwaye emva koko ugqume ubushushu obuphezulu. Isilivere yebrazing flux inomsebenzi kuluhlu lobushushu obuphantsi, kwaye iqondo lobushushu elisebenzayo lobushushu obuphezulu bunokufikelela kwi-1427 ℃.

Amacandelo e-TA okanye e-Nb akhethwa ukuba agxininiswe phantsi kwe-vacuum, kwaye i-degree ye-vacuum ayikho ngaphantsi kwe-1.33 × 10-2Pa. Ukuba i-brazing iqhutyelwa phantsi kokukhuselwa kwegesi ye-inert, ukungcola kwegesi njenge-carbon monoxide, i-ammonia, i-nitrogen kunye ne-carbon dioxide kufuneka isuswe ngokungqongqo. Xa ukubethelwa okanye ukuchasana kuqhutyelwa emoyeni, isinyithi esikhethekileyo sokugcwalisa isinyithi kunye ne-flux efanelekileyo iya kusetyenziswa. Ukuze kuthintelwe i-TA okanye i-Nb ekudibaneni ne-oksijini kwiqondo lokushisa eliphezulu, umaleko wobhedu okanye i-nickel yensimbi inokugqithwa phezu komhlaba kwaye unyango oluhambelanayo lwe-annealing lunokwenziwa.

Ixesha lokuposa: Jun-13-2022