Ukuxutywa kwentsimbi engenasici

1. Ukuba nesibindi

Ingxaki ephambili kwi-stainless steel brazing kukuba ifilimu ye-oxide ebusweni ichaphazela kakhulu ukumanzisa kunye nokusabalalisa i-solder. Iintsimbi ezininzi ezingenasici ziqulethe inani elikhulu le-Cr, kwaye ezinye ziqulethe i-Ni, i-Ti, i-Mn, i-Mo, i-Nb kunye nezinye izinto, ezinokuthi zenze iindidi zee-oxides okanye ii-oxide ezidibeneyo phezu komhlaba. Phakathi kwazo, iioksidi ze-Cr2O3 kunye ne-TiO2 ye-Cr kunye ne-Ti zizinzile kwaye kunzima ukuzisusa. Xa utshisa emoyeni, i-flux esebenzayo kufuneka isetyenziswe ukususa; Xa ubhobhoza kwi-atmosphere ekhuselayo, ifilimu ye-oxide ingancitshiswa kuphela kwi-atmospheric ephezulu yokucoceka kunye neqondo eliphantsi lombethe kunye nokushisa okwaneleyo; Kwi-vacuum brazing, kuyimfuneko ukuba ube ne-vacuum eyaneleyo kunye nobushushu obaneleyo ukuze ufezekise umphumo omuhle wokuqhawula.

Enye ingxaki yokubethelwa kwensimbi engenasici kukuba ubushushu bokufudumala bunefuthe elibi kwisakhiwo sesiseko sesinyithi. Iqondo lobushushu lokutshisa i-austenitic stainless steel aliyi kuba ngaphezulu kwe-1150 ℃, kungenjalo iinkozo ziya kukhula ngokunzulu; Ukuba i-austenitic stainless steel ayinayo into ezinzileyo ye-Ti okanye i-Nb kwaye inomxholo ophezulu wekhabhoni, i-brazing ngaphakathi kweqondo lokushisa le-sensitization (500 ~ 850 ℃) nayo iya kuphetshwa. Ukuthintela ukuxhathisa umhlwa ekunciphiseni ngenxa yemvula ye-chromium carbide. Ukukhethwa kweqondo lokushisa lokutshisa intsimbi ye-martensitic ingqongqo ngakumbi. Omnye ukudibanisa ubushushu bokushisa kunye nobushushu bokucima, ukwenzela ukuba udibanise inkqubo yokuqhawula kunye nenkqubo yokunyanga ukushisa; Enye into yokuba ukushisa kwe-brazing kufuneka kube ngaphantsi kweqondo lokushisa lokufudumala ukukhusela isiseko sesinyithi ekunciphiseni ngexesha lokugcoba. Umgaqo wokukhethwa kweqondo lokushisa lokutshisa i-precipitation ukuqina kwensimbi engenasici kufana ne-martensitic stainless steel, oko kukuthi, ukushisa okutshisayo kufuneka kuhambelane nenkqubo yokunyanga ukushisa ukuze kufumaneke iimpawu ezingcono kakhulu zomatshini.

Ukongeza kwezi ngxaki zimbini zingasentla, kukho ukuthambekela kokuqhekeka koxinzelelo xa ubrawuza i-austenitic stainless steel, ngakumbi xa uqhayiya nge-copper zinc filler metal. Ukuze ugweme ukukrazuka koxinzelelo, i-workpiece iya kuncitshiswa i-annealed annealed phambi kokubhobhoza, kwaye i-workpiece iya kufudunyezwa ngokufanayo ngexesha lokuqhaqha.

2. Izinto zokubrasha

(1) Ngokweemfuno zokusetyenziswa kweentsimbi zensimbi ezingenasici, isinyithi esisekwe kwintsimbi yentsimbi, isinyithi esisekwe kwintsimbi, i-nickel esekwe kwintsimbi yokuqhafaza kunye nentsimbi exabisekileyo.

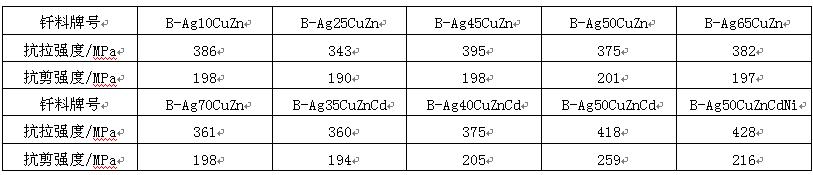

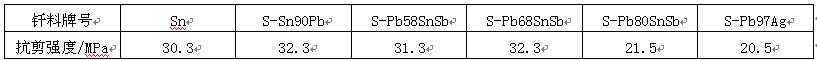

I-Tin lead solder isetyenziswa ikakhulu kwi-stainless steel soldering, kwaye ifanelekile ukuba ibe nomxholo ophezulu we-tin. Ukuphakama kwe-tin ye-solder, ngcono ukumanzi kwayo kwintsimbi engenasici. Amandla e-shear ye-1Cr18Ni9Ti edibeneyo yensimbi engenasici edityanisiweyo kunye nee-solders ezininzi eziqhelekileyo ze-tin zidweliswe kwiThebhile 3. Ngenxa yamandla aphantsi adibeneyo, asetyenziselwa kuphela iindawo zokubhobhoza ezinomthamo omncinci wokuthwala.

Itheyibhile 3 yamandla okucheba ye-1Cr18Ni9Ti yentsimbi edibeneyo edityaniswe nge-tin lead solder

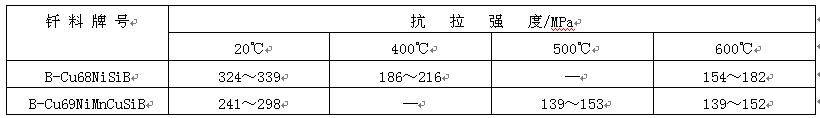

Iintsimbi zokuzalisa ezisekwe kwisilivere zezona ziqhelekileyo zisetyenziswa kwintsimbi yokufaka intsimbi. Phakathi kwazo, isilivere yethusi ye-zinc kunye nesilivere yethusi ye-zinc cadmium filler metals zisetyenziswa kakhulu kuba ubushushu bokutshisa bunempembelelo encinci kwiipropathi zesiseko sesinyithi. Amandla e-ICr18Ni9Ti yentsimbi yensimbi engenasici edityanisiweyo kunye nee-solder ezininzi eziqhelekileyo ezisekelwe kwisilivere zidweliswe kwiThebhile 4. Izixhobo zensimbi ezingenasici ezidityanisiweyo kunye nee-solder ezisekelwe kwisilivere azifane zisetyenziswe kwimidiya enobungozi kakhulu, kwaye ukushisa okusebenzayo kwamalungu ngokubanzi akudluli kwi-300 ℃. Xa ubrawuza intsimbi engatyiwayo ngaphandle kwe-nickel, ukuze kuthintelwe ukubola kwejoyinti lebrazed kwindawo efumileyo, kuya kusetyenziswa isinyithi sokubrawuza esine-nickel eninzi, njenge-b-ag50cuzncdni. Xa ubhobhoza intsimbi ye-martensitic, ukuze kuthintelwe ukuthamba kwesiseko sesinyithi, isinyithi sokuqhafaza esinobushushu obungadluliyo kuma-650 ℃ siya kusetyenziswa, njenge-b-ag40cuzncd. Xa ubhobhoza insimbi engenasici kwi-atmosphere ekhuselayo, ukuze kususwe ifilimu ye-oxide phezu komhlaba, i-lithium equkethe i-self brazing flux ingasetyenziswa, njenge-b-ag92culi kunye ne-b-ag72culi. Xa ubhobhoza insimbi engenasici kwi-vacuum, ukwenzela ukuba insimbi yokuzalisa ihlale imanzi kakuhle xa ingenayo izinto ezifana ne-Zn kunye ne-CD ekulula ukuyikhupha, i-filler metal metal equkethe izinto ezifana ne-Mn, i-Ni kunye ne-RD inokukhethwa.

Itheyibhile 4 amandla e-ICr18Ni9Ti yentsimbi edibeneyo edityaniswe ngentsimbi esekwe kwisilivere

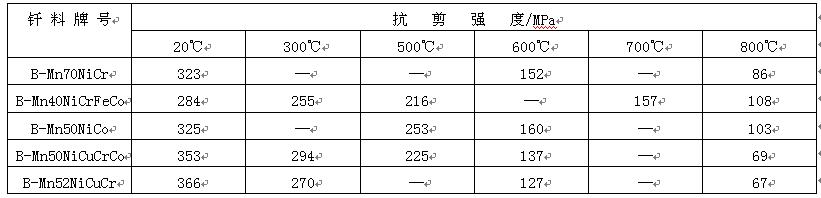

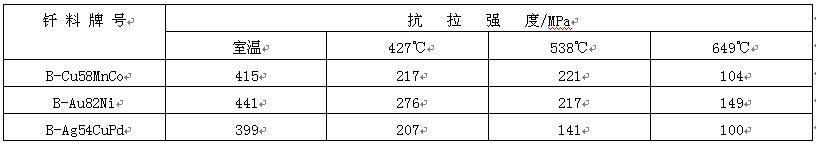

Isinyithi esekwe kubhedu esekwe kwibrazing esetyenziselwa ukujongisa iintsimbi ezahlukeneyo ikakhulu lubhedu olusulungekileyo, i-nickel yobhedu kunye nesinyithi se-manganese cobalt brazing brazing filler. Isinyithi esisulungekileyo sokuqhafaza kwentsimbi sisetyenziselwa ukubethelwa phantsi kokhuseleko lwegesi okanye i-vacuum. Iqondo lobushushu elisebenzayo lentsimbi engenasici alikho ngaphezulu kwe-400 ℃, kodwa ijoyini inokumelana ne-oxidation embi. I-copper nickel brazing filler metal isetyenziselwa ikakhulu ukuvutha amadangatye kunye ne-induction brazing. Amandla e-brazed 1Cr18Ni9Ti edibeneyo yensimbi engenasici iboniswe kwiThebhile 5. Ingabonwa ukuba umdibaniso unamandla afanayo kunye nesiseko sesinyithi, kwaye ukushisa okusebenzayo kuphezulu. I-Cu Mn co brazing filler metal isetyenziselwa ikakhulu ukubrawuza intsimbi ye-martensitic engatyiwa kwindawo ekhuselayo. Amandla adibeneyo kunye nobushushu bokusebenza bufaniswa nalawo afakwe ngegolide esekwe kwintsimbi yokuzalisa. Ngokomzekelo, i-1Cr13 i-stainless steel joint brazed kunye ne-b-cu58mnco solder inomsebenzi ofanayo kunye ne-stainless steel joint joint brazed nge-b-au82ni solder (jonga i-Table 6), kodwa iindleko zokuvelisa ziyancipha kakhulu.

Itheyibhile ye-5 yamandla okucheba ye-1Cr18Ni9Ti yentsimbi edibeneyo edityaniswe ngobushushu obuphezulu besiseko sentsimbi.

Itheyibhile 6 amandla okucheba 1Cr13 steel stainless brazed joint

I-Manganese esekwe kwibrazing metal metals isetyenziswa ikakhulu kwi-gas shielded brazing, kwaye ubunyulu berhasi kufuneka buphakame. Ukuze ugweme ukukhula okuziinkozo kwesiseko sesinyithi, isinyithi esihambelanayo sokuzalisa intsimbi kunye nobushushu bokutshisa obungaphantsi kwe-1150 ℃ kufuneka kukhethwe. Umphumo owanelisayo wokubhobhoza unokufumaneka kwiintsimbi zensimbi ezingenasici ezixutywe nge-solder esekelwe kwi-manganese, njengoko kuboniswe kwiThebhile 7. Ukushisa okusebenzayo komdibaniso kunokufikelela kwi-600 ℃.

Itheyibhile 7 amandla okucheba ye-lcr18ni9fi yentsimbi edibeneyo edityaniswe ngesinyithi esekwe manganese

Xa intsimbi engenastainless idityaniswe ngentsimbi ye-nickel base filler, umdibaniso unomsebenzi olungileyo wobushushu obuphezulu. Le ntsimbi yokuzalisa isetyenziswa ngokubanzi kwi-gas shielded brazing okanye i-vacuum brazing. Ukuze unqobe ingxaki yokuba iikhompawundi ezinqabileyo ezingaphezulu ziveliswa kwi-brazed joint ngexesha lokubunjwa okuhlangeneyo, okunciphisa kakhulu amandla kunye neplastiki ye-joint, i-gap edibeneyo kufuneka incitshiswe ukuze kuqinisekiswe ukuba izinto ezilula ukwenza isigaba se-brittle kwi-solder zisasazwe ngokupheleleyo kwisiseko sesinyithi. Ukuze kuthintelwe ukwenzeka kwesiseko sokukhula kwengqolowa yentsimbi ngenxa yokubamba ixesha elide kwiqondo lokushisa lokutshisa, imilinganiselo yenkqubo yokubamba ixesha elifutshane kunye nokusabalalisa unyango kwiqondo lokushisa eliphantsi (xa kuthelekiswa nobushushu bokushisa) emva kokuba i-welding ingathathwa.

Iintsimbi zokuzalisa isinyithi esinobulunga ezisetyenziselwa ukubrawuza intsimbi engenasici ikakhulu zibandakanya isinyithi esekwe kwigolide kunye ne-palladium equlathe iintsimbi zokuzalisa, ezona ziqhelekileyo ziyi-b-au82ni, b-ag54cupd kunye ne-b-au82ni, ezinobumanzi obuhle. Umdibaniso wensimbi engenasici unamandla aphezulu aphezulu kunye nokumelana ne-oxidation, kwaye ubushushu obuphezulu bokusebenza bunokufikelela kuma-800 ℃. I-B-ag54cupd ineempawu ezifanayo kwi-b-au82ni kwaye ixabiso layo liphantsi, ngoko idla ngokuthatha indawo ye-b-au82ni.

(2) Umphezulu wensimbi engenasici kwi-flux kunye ne-furnace atmosphere iqukethe i-oxides efana ne-Cr2O3 kunye ne-TiO2, enokususwa kuphela ngokusebenzisa i-flux kunye nomsebenzi onamandla. Xa insimbi engenasici idityaniswe nge-tin lead solder, i-flux efanelekileyo yi-phosphoric acid isisombululo se-aqueous okanye isisombululo se-zinc oxide hydrochloric acid. Ixesha lomsebenzi we-phosphoric acid isisombululo se-aqueous sifutshane, ngoko ke indlela yokuqhayisa yokufudumala ngokukhawuleza kufuneka yamkelwe. I-Fb102, i-fb103 okanye i-fb104 fluxes ingasetyenziselwa ukubhobhoza isinyithi esingenasici ngesinyithi esisekelwe kwisilivere. Xa ubhobhoza intsimbi engenasici ngesinyithi esekwe kwi-filler, i-fb105 flux isetyenziswa ngenxa yobushushu obuphezulu bokugquma.

Xa ubhobhoza isinyithi esingenasici esithandweni, umoya we-vacuum okanye umoya okhuselayo onjenge-hydrogen, i-argon kunye ne-ammonia yokubola isoloko isetyenziswa. Ngexesha lokucoca i-vacuum, uxinzelelo lwe-vacuum luya kuba ngaphantsi kwe-10-2Pa. Xa ubhobhoza kwindawo ekhuselayo, indawo yombethe yerhasi ayiyi kuba ngaphezulu kwe -40 ℃ Ukuba ukucoceka kwerhasi akwanelanga okanye ubushushu bokutshisa abukho phezulu, umlinganiselo omncinci wegesi yokutshisa igesi, efana ne-boron trifluoride, unokongezwa emoyeni.

2. Iteknoloji yokubrawuza

Intsimbi engatyiwayo kufuneka icocwe ngokungqongqo ngakumbi phambi kokuba ibrashi isuse nayiphi na igrisi kunye nefilimu yeoli. Kungcono ukugcoba ngokukhawuleza emva kokucoca.

Ukunyanyiswa kwensimbi engenasici kunokusebenzisa idangatye, ukungenisa kunye neendlela zokufudumeza eziphakathi kwesithando somlilo. Isithando somlilo sokutshisa kwisithando somlilo kufuneka sibe nenkqubo yokulawula ubushushu obulungileyo (ukuphambuka kobushushu bokushisa kufuneka kube ± 6 ℃) kwaye kunokupholiswa ngokukhawuleza. Xa i-hydrogen isetyenziswa njengegesi ekhuselayo yokuqhaqha, iimfuno ze-hydrogen zixhomekeke kwiqondo lokushisa lokuqhaqha kunye nokubunjwa kwesiseko sesinyithi, oko kukuthi, ukufudumala kweqondo lokushisa eliphantsi, ngakumbi isiseko sesinyithi siqulethe i-stabilizer, kwaye isezantsi indawo yombethe ye-hydrogen iyafuneka. Umzekelo, kwiintsimbi ze-martensitic stainless ezifana ne-1Cr13 kunye ne-cr17ni2t, xa i-brazing kwi-1000 ℃, indawo yombethe ye-hydrogen kufuneka ibe ngaphantsi kwe-40 ℃; Kwi-18-8 ye-chromium nickel yensimbi engenazinzisi, indawo yombethe ye-hydrogen iya kuba ngaphantsi kwe-25 ℃ ngexesha lokuqhayisa kwi-1150 ℃; Nangona kunjalo, kwintsimbi ye-1Cr18Ni9Ti engenastainless ene-titanium stabilizer, indawo yombethe we-hydrogen kufuneka ibe ngaphantsi kwe--40 ℃ xa ibhuqa kwi-1150 ℃. Xa ubhobhoza ngokhuseleko lwe-argon, ukucoceka kwe-argon kuyadingeka ukuba kube phezulu. Ukuba ubhedu okanye i-nickel ifakwe phezu kwendawo yensimbi engenasici, imfuneko yokucoceka kwegesi yokukhusela ingancitshiswa. Ukuqinisekisa ukususwa kwefilimu ye-oxide kumphezulu wensimbi engenasici, i-BF3 i-gas flux nayo inokongezwa, kunye ne-lithium okanye i-boron equlethe i-self flux solder nayo ingasetyenziswa. Xa vacuum brazing steel stainless, iimfuno zesidanga vacuum zixhomekeke ubushushu brazing. Ngokunyuka kweqondo lokushisa, i-vacuum efunekayo ingancitshiswa.

Inkqubo ephambili yensimbi engenasici emva kokugcoba kukucoca i-flux eseleyo kunye ne-residual flow inhibitor, kwaye uqhube unyango lwe-post brazing ukushisa ukuba kuyimfuneko. Ngokuxhomekeke kwindlela yokuguqa kunye ne-brazing esetyenzisiweyo, i-flux eseleyo inokuhlanjwa ngamanzi, icocwe ngoomatshini okanye icocwe ngamachiza. Ukuba i-abrasive isetyenziselwa ukucoca i-flux eseleyo okanye ifilimu ye-oxide kwindawo efudumeleyo kufuphi nomdibaniso, isanti okanye ezinye iincinci ezingenayo isinyithi ziya kusetyenziswa. Amacandelo enziwe nge-martensitic steel stainless kunye nemvula eqinisa insimbi engenasici idinga unyango lobushushu ngokweemfuno ezikhethekileyo zezinto emva kokuqhayisa. Amalungu ensimbi engenasici adityaniswe ngentsimbi ye-Ni Cr B kunye ne-Ni Cr Si yokuzalisa iintsimbi zihlala ziphathwa ngobushushu bokusasazwa konyango emva kokubrawuza ukunciphisa iimfuno zomsantsa wokuqhawuka kunye nokuphucula i-microstructure kunye neepropathi zamalungu.

Ixesha lokuposa: Jun-13-2022