Ukuxutywa kweSuperalloys

(1) Iimpawu ze-brazing superalloys zingahlulwa zibe ngamacandelo amathathu: isiseko se-nickel, isiseko sentsimbi kunye nesiseko se-cobalt. Zineempawu ezintle zoomatshini, ukuxhathisa i-oxidation kunye nokumelana nokugqwala kumaqondo aphezulu. I-nickel base alloy yeyona nto isetyenziswa kakhulu kwimveliso ebonakalayo.

I-superalloy iqulethe i-Cr engaphezulu, kunye nefilimu ye-oxide ye-Cr2O3 enzima ukuyisusa yenziwe phezulu ngexesha lokufudumala. I-nickel base superalloys iqulethe i-Al kunye ne-Ti, ekulula ukuyikhupha xa ishushu. Ngoko ke, ukuthintela okanye ukunciphisa i-oxidation ye-superalloys ngexesha lokufudumala kunye nokususa ifilimu ye-oxide yingxaki ephambili ngexesha lokugcoba. Njengoko i-borax okanye i-boric acid kwi-flux ingabangela ukubola kwesiseko sesinyithi kwiqondo lokushisa lokutshisa, i-boron ehlanjululwayo emva kokuba impendulo ingangena kwisiseko sesinyithi, okubangelwa ukungena kwe-intergranular. Kwi-alloys yesiseko se-nickel ephonsiweyo kunye neziqulatho eziphezulu ze-Al kunye ne-Ti, idigri ye-vacuum kwindawo eshushu ayiyi kuba ngaphantsi kwe-10-2 ~ 10-3pa ngexesha lokugcoba ukuphepha i-oxidation kwi-alloy surface ngexesha lokufudumala.

Ukuze isisombululo esomeleziweyo kunye nemvula yomeleza i-alloys yesiseko se-nickel, ubushushu bokutshisa kufuneka buhambelane nobushushu bokufudumala bonyango lwesisombululo ukuqinisekisa ukuchithwa ngokupheleleyo kwezinto ze-alloy. Ukushisa okutshisayo kuphantsi kakhulu, kwaye izinto ze-alloy azikwazi ukuchithwa ngokupheleleyo; Ukuba ubushushu bokushisa buphezulu kakhulu, isiseko sentsimbi siya kukhula, kwaye izinto eziphathekayo aziyi kubuyiselwa nangemva kokunyanga ukushisa. Ubushushu besisombululo esiqinileyo se-cast base base alloys buphezulu, obungayi kuchaphazela iipropathi zezinto eziphathekayo ngenxa yobushushu obuphezulu kakhulu.

Ezinye ze-nickel base superalloys, ngakumbi imvula eyomeleziweyo yealloys, inotyekelo lokuqhekeka koxinzelelo. Ngaphambi kokutshiza, uxinzelelo olwenziwe kwinkqubo kufuneka lususwe ngokupheleleyo, kwaye uxinzelelo lwe-thermal kufuneka luncitshiswe ngexesha lokugcoba.

(2) I-alloy yesiseko se-nickel ye-brazing inokugqithwa ngesiseko sesilivere, ubhedu olucocekileyo, isiseko se-nickel kunye ne-solder esebenzayo. Xa ubushushu bokusebenza komdibaniso bungekho phezulu, izixhobo ezisekelwe kwisilivere zingasetyenziswa. Kukho iintlobo ezininzi zee-solder zesilivere. Ukuze unciphise uxinzelelo lwangaphakathi ngexesha lokufudumala kwe-brazing, kungcono ukhethe i-solder ngeqondo lokushisa eliphantsi. I-Fb101 flux ingasetyenziselwa ukugcoba ngentsimbi yesiseko sesilivere. I-Fb102 flux isetyenziselwa i-brazing precipitation iqiniswe i-superalloy enomxholo ophezulu we-aluminium, kunye ne-10% ~ 20% ye-sodium silicate okanye i-aluminium flux (efana ne-fb201) yongezwa. Xa iqondo lobushushu lokubrawuza lingaphezulu kwe-900 ℃, i-fb105 flux iya kukhethwa.

Xa ubhobhoza kwi-vacuum okanye umoya okhuselayo, ubhedu olusulungekileyo lunokusetyenziswa njengentsimbi yokuqhafaza. Iqondo lokushisa lokutshisa liyi-1100 ~ 1150 ℃, kwaye umdibaniso awuyi kuvelisa ukuphazamiseka koxinzelelo, kodwa ukushisa okusebenzayo akuyi kudlula i-400 ℃.

I-nickel base brazing filler metal sesona sixhaphakileyo sisetyenziswa kwi-brazing filler metal kwiSuperalloys ngenxa yokusebenza kwayo kakuhle kobushushu obuphezulu kwaye akukho xinzelelo lokuqhekeka ngexesha lokugqabhuka. Izinto eziphambili ze-alloy kwi-solder ye-nickel yi-Cr, i-Si, i-B, kunye nenani elincinci le-solder nalo liqulethe i-Fe, W, njl njl. Xa kuthelekiswa ne-ni-cr-si-b, i-b-ni68crwb yokuqhafaza isinyithi ye-brazing inokunciphisa ukungena kwe-intergranular ye-B kwisiseko sesinyithi kunye nokwandisa ixesha lobushushu obunyibilikayo. Yintsimbi yokuzalisa i-brazing yokubraya iindawo zokusebenza ezinobushushu obuphezulu kunye neeblade ze-injini. Nangona kunjalo, i-fluidity ye-solder ene-W iba mbi kwaye i-gap edibeneyo kunzima ukuyilawula.

Intsimbi esebenzayo yokuqhafaza ibrazing ayinayo i-Si element kwaye inokumelana ne-oxidation ebalaseleyo kunye nokumelana ne-vulcanization. Iqondo lokushisa lokutshisa linokukhethwa ukusuka kwi-1150 ℃ ukuya kwi-1218 ℃ ngokohlobo lwe-solder. Emva kokuqhaqha, i-brazed joint eneempawu ezifanayo njengesiseko sesinyithi inokufumaneka emva kwe-1066 ℃ yonyango lokusasazwa.

(3) Inkqubo yokutshisa i-nickel base alloy inokwamkela ukubrawuza kwisithando somlilo esikhuselayo, i-vacuum brazing kunye noqhagamshelwano lwesigaba solwelo oludlulayo. Phambi kokubrawuza, umphezulu kufuneka uthotywe igrisi kunye neoksidi isuswe ngokulungiswa kwesanti, ukupolisha kwevili, ukukhuhla iacetone kunye nokucoca imichiza. Xa ukhetha iiparameters zenkqubo yokubhobhoza, kufuneka kuqatshelwe ukuba ubushushu bokufudumala akufanele buphakame kakhulu kwaye ixesha lokuqhawula kufuneka libe lifutshane ukuphepha ukusabela kweekhemikhali ezinamandla phakathi kwe-flux kunye nesiseko sesinyithi. Ukuze kuthintelwe isiseko sesinyithi ekuqhekekeni, iinxalenye ezicwangcisiweyo ezibandayo ziya kuxinzezeleka phambi kwe-welding, kwaye ukufudumeza kwe-welding kuya kufana ngokusemandleni. Kwimvula eyomeleziweyo ye-superalloys, iindawo ziya kuxhomekeka kunyango lwesisombululo esiluqilima kuqala, emva koko zifakwe kwiqondo lobushushu elingaphezulu kancinci kunonyango lokomeleza ukwaluphala, kwaye ekugqibeleni unyango lokuguga.

I-1) Ukutshisa kwindawo ekhuselayo yesithando somlilo kwisithando somlilo esikhuselayo kufuna ukucoceka okuphezulu kwegesi yokukhusela. Kwi-superalloys ene-w (AL) kunye ne-w (TI) ngaphantsi kwe-0.5%, indawo yombethe iya kuba ngaphantsi kwe -54 ℃ xa kusetyenziswa i-hydrogen okanye i-argon. Xa umxholo we-Al kunye no-Ti usanda, i-alloy surface isasebenza xa ishushu. La manyathelo alandelayo kufuneka athathwe; Yongeza inani elincinci le-flux (njenge-fb105) kwaye ususe ifilimu ye-oxide nge-flux; I-0.025 ~ 0.038mm i-coat etyebileyo ifakwe kumphezulu weendawo; Ukutshiza i-solder kumphezulu wezinto eziza kubhengezwa kwangaphambili; Yongeza umlinganiselo omncinci wegesi, njenge-boron trifluoride.

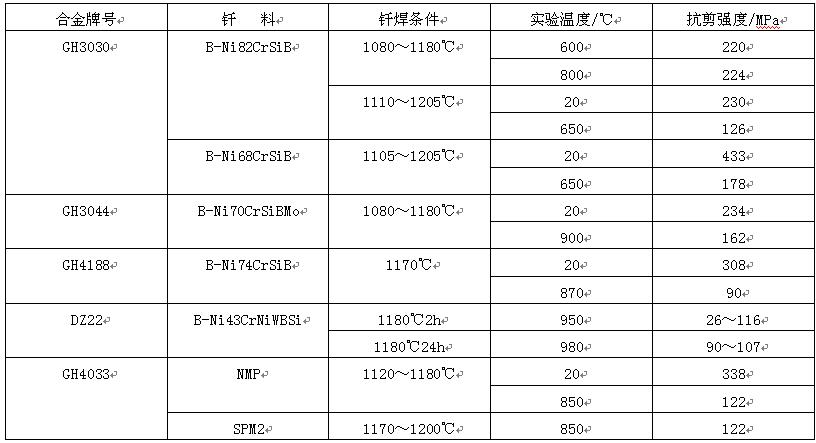

I-2) I-vacuum ye-vacuum ye-vacuum isetyenziselwa ngokubanzi ukufumana umphumo ongcono wokukhusela kunye nomgangatho wokugcoba. Jonga kwitheyibhile ye-15 malunga neempawu zomatshini we-nickel base base superalloy joints. Kuba superalloys kunye w (AL) kunye w (TI) ngaphantsi kwe-4%, kungcono electroplate umaleko 0.01 ~ 0.015mm nickel kumphezulu, nangona ukumanzisa solder kunokuqinisekisa ngaphandle pretreatment ekhethekileyo. Xa i-w (AL) kunye ne-w (TI) idlula i-4%, ubukhulu be-nickel coating buya kuba yi-0.020.03mm. I-coating encinci kakhulu ayinayo impembelelo yokukhusela, kwaye i-coating too thick iya kunciphisa amandla okudibanisa. Amalungu adityanisiweyo nawo anokufakwa kwibhokisi yokucoca ivacuum. Ibhokisi kufuneka igcwaliswe nge-getter. Ngokomzekelo, i-Zr ithatha igesi kwiqondo lokushisa eliphezulu, elinokwenza i-vacuum yendawo kwibhokisi, ngaloo ndlela ikhusela i-oxidation ye-alloy surface.

Itheyibhuli eyi-15 yeepropathi zoomatshini zeVacuum Brazed Joints yesiqhelo ye-nickel base superalloys

I-microstructure kunye namandla e-brazed joint of the Superalloy change with the gap brazing, kunye ne-diffusion treatment after brazing iya kwandisa ngakumbi ixabiso elivumelekileyo le-gap edibeneyo. Ukuthatha i-Inconel alloy njengomzekelo, i-gap enkulu ye-Inconel joint brazed kunye ne-b-ni82crsib inokufikelela kwi-90um emva kokunyangwa kwe-diffusion kwi-1000 ℃ ye-1H; Nangona kunjalo, kwi-joints brazed nge-b-ni71crsib, i-gap ephezulu imalunga ne-50um emva konyango lokusasazwa kwi-1000 ℃ ye-1H.

3) Uqhagamshelo lwesigaba solwelo oludlulayo ludibaniso lwesigaba solwelo oludlulayo lusebenzisa i-alloy ye-interlayer (malunga ne-2.5 ~ 100um ubukhulu) apho indawo yokunyibilika ingaphantsi kunesiseko sesinyithi njengentsimbi yokuzalisa. Phantsi koxinzelelo oluncinci (0 ~ 0.007mpa) kunye nobushushu obufanelekileyo (1100 ~ 1250 ℃), i-interlayer imathiriyeli yokuqala iyanyibilika kwaye inyakamisa isiseko sesinyithi. Ngenxa yokusasazwa ngokukhawuleza kwezinto, ukuqina kwe-isothermal kwenzeka kwijoyinti ukuze kuhlangane. Le ndlela inciphisa kakhulu iimfuno ezihambelanayo zesiseko sesinyithi kunye nokunciphisa uxinzelelo lwe-welding. Iiparamitha eziphambili zoqhagamshelwano lwesigaba solwelo oludlulayo luxinzelelo, ubushushu, ixesha lokubamba kunye nokubunjwa kwe-interlayer. Faka uxinzelelo oluncinci ukugcina umphezulu wokukhwelana weldment unxibelelana kakuhle. Ukufudumala kweqondo lokushisa kunye nexesha kunempembelelo enkulu ekusebenzeni komdibaniso. Ukuba umdibaniso kufuneka ube namandla njengesiseko sesinyithi kwaye awuchaphazeli ukusebenza kwesiseko sesinyithi, imilinganiselo yenkqubo yokudibanisa iqondo lokushisa eliphezulu (njenge-≥ 1150 ℃) kunye nexesha elide (elifana ne-8 ~ 24h) liya kwamkelwa; Ukuba umgangatho wokudibanisa umdibaniso uyancitshiswa okanye isiseko sesinyithi asikwazi ukumelana nokushisa okuphezulu, ukushisa okuphantsi (1100 ~ 1150 ℃) kunye nexesha elifutshane (1 ~ 8h) liya kusetyenziswa. Umaleko ophakathi uya kuthatha isiseko edityanisiweyo ukubunjwa metal njengoko ukwakheka esisiseko, kwaye yongeza izinto ezahlukeneyo zokupholisa, ezifana B, Si, Mn, Nb, njl Umzekelo, ukubunjwa Udimet ingxubevange ni-15cr-18.5co-4.3al-3.3ti-5mo, kunye nokuqulunqwa umaleko eliphakathi udibaniso lwexeshana ulwelo lwexeshana b-55cmoni162. Zonke ezi zinto zinokunciphisa ukushisa okunyibilikayo kwe-Ni Cr okanye i-Ni Cr Co alloys ukuya kweyona nto iphantsi, kodwa umphumo we-B ngowona ucacileyo. Ukongeza, izinga eliphezulu lokusasazwa kwe-B linokwenza i-homogenize ngokukhawuleza i-alloy ye-interlayer kunye nesiseko sesinyithi.

Ixesha lokuposa: Jun-13-2022