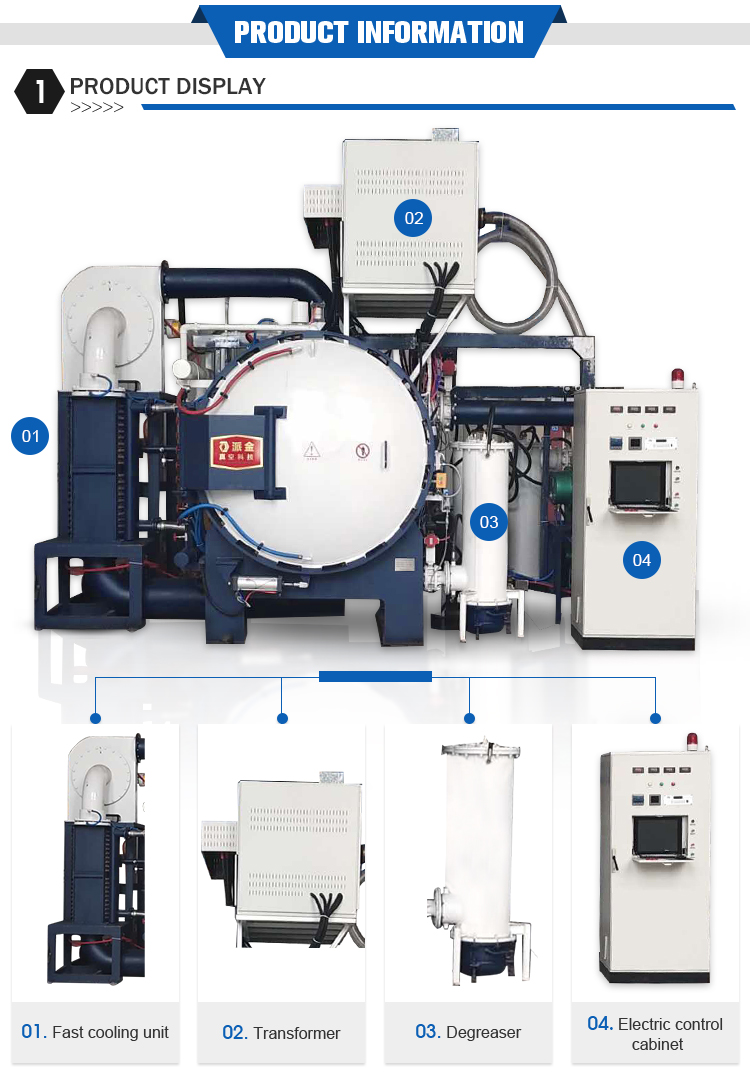

I-vacuum Debinding kunye ne-Sintering furnace (Isithando se-MIM, isithando somgubo sesinyithi)

Iimpawu

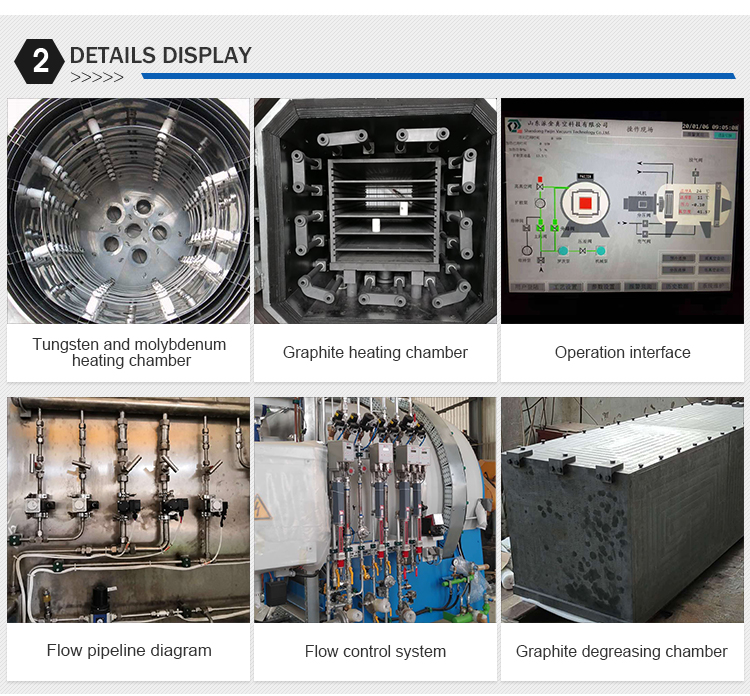

1. Graphite insulation screen / metal screen ozikhethelayo, ukufudumeza element 360 degree surround radiation ukufudumeza, uyilo oluthembekileyo ukugquma.

2. Ukushisa okuphezulu okufanayo kunye nokusebenza kakuhle kwe-thermal

3. Vacuum inxenye yoxinzelelo / umsebenzi wokulawula ubushushu bendawo ezininzi.

4. Izixhobo ezizenzekelayo ngokupheleleyo, ukhuseleko olugqibeleleyo kunye nenkqubo ye-alamu engaqhelekanga.

5. Ukulawulwa kwenkqubo echanekileyo ukufezekisa umgangatho wenxalenye ehambelanayo kunye nokuthintela ukungcoliseka kwamalungu kunye neendawo ezishushu.

6. Ngebhokisi yokucoca etywiniweyo kunye ne-vacuum condenser ukunciphisa ukungcola kwegumbi lokufudumeza kunye neyunithi.

7.Thintela ungcoliseko kumacandelo eziko. Ibhokisi ye-square degreasing isetyenziselwa ukujongana nenani elikhulu lezongezo zokubumba.

8. Inemisebenzi ye-flexible vacuum extraction, i-vacuum sintering, i-micro-positive pressure sintering njalo njalo.

9. Ukwakhiwa kwe-thermal insulation yamva nje kunye nezinto eziphathekayo zisetyenzisiweyo, ukunyanzeliswa koxinzelelo kunamandla, kwaye ukugcinwa kwamandla kubonakala.

I-10.Inemisebenzi yokushisa okugqithisileyo kunye ne-alamu yoxinzelelo, ukhuseleko loxinzelelo oluzenzekelayo ngomatshini, ngokuzenzekelayoukukhuselwa koxinzelelo olugqithisileyo, ukudibanisa isenzo kunye nokunye, ukhuseleko lwezixhobo eziphezulu.

I-11.Ukusebenza okude, ukuxilongwa kwempazamo ekude kunye nemisebenzi yokuphucula isofthiwe ekude, njl.

Ukuchazwa kwemodeli esemgangathweni kunye neeparamitha

| Umzekelo | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Indawo esebenzayo eshushu LWH (mm) | 200*200* 300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| Ubunzima bomthwalo(kg) | 100 | 200 | 400 | 600 | 10000 |

| Amandla okufudumeza (kw) | 65 | 80 | 150 | 200 | 450 |

| Obona bushushu bobushushu(℃) | 1600 | ||||

| Ukuchaneka kokulawula ubushushu(℃) | ±1 | ||||

| Ukuhambelana kobushushu beziko(℃) | ±3 | ||||

| Idigri yevacuum yomsebenzi (Pa) | 4.0 * E -1 | ||||

| Amazinga okumpompa (ukuya ku-5 pa) | ≤10 imiz | ||||

| Izinga lokunyuswa koxinzelelo (Pa/H) | ≤ 0.5 | ||||

| Ixabiso lokuboleka | >97.5% | ||||

| Indlela yokudibanisa | N2 kuxinzelelo olubi, H2 emoyeni | ||||

| Irhasi yokufaka | N2, H2, Ar | ||||

| Indlela yokupholisa | ukupholisa irhasi ye-inert | ||||

| Indlela yeSintering | Ivacuum sintering, inxenye yoxinzelelo lokuntywila, ukuntywila ngaphandle koxinzelelo | ||||

| Ukwakhiwa kwesithando somlilo | Ihorizontal, igumbi elinye | ||||

| Indlela yokuvula umnyango wesithando somlilo | Uhlobo lwehinge | ||||

| Izinto zokufudumeza | Izinto zokufudumeza iGraphit | ||||

| Igumbi lokufudumeza | Ubume bokwakheka kweGraphit ivakala nzima kwaye ivakala ithambile | ||||

| Thermocouple | C Uhlobo | ||||

| I-PLC kunye nezinto zombane | Siemens | ||||

| Umlawuli wobushushu | EUROTHERM | ||||

| Impompo yokufunxa | Impompo yoomatshini kunye nempompo yeengcambu | ||||

| Uluhlu olukhethiweyo olukhethiweyo | |||||

| Ubushushu obuninzi | 1300-2800 ℃ | ||||

| Ubuninzi beqondo lobushushu | 6.7 * E -3 Pa | ||||

| Ukwakhiwa kwesithando somlilo | Ukuthe tye, nkqo, igumbi elinye | ||||

| Indlela yokuvula umnyango | Uhlobo lwehinge, Uhlobo lokuphakamisa, uhlobo lweFlethi | ||||

| Izinto zokufudumeza | Izinto zokufudumeza zeGraphit, izinto zokufudumeza zeMo | ||||

| Igumbi lokufudumeza | Igraphit eyakhiweyo ivakale, Yonke intsimbi ebonisa isikrini | ||||

| Iimpompo zokufunxa | impompo yoomatshini kunye nempompo yeengcambu; Oomatshini, iingcambu kunye neempompo zokusasaza | ||||

| I-PLC kunye nezinto zombane | Siemens; uOmron; iMitsubishi; Siemens | ||||

| Umlawuli wobushushu | EUROTHERM;S HIMADEN | ||||